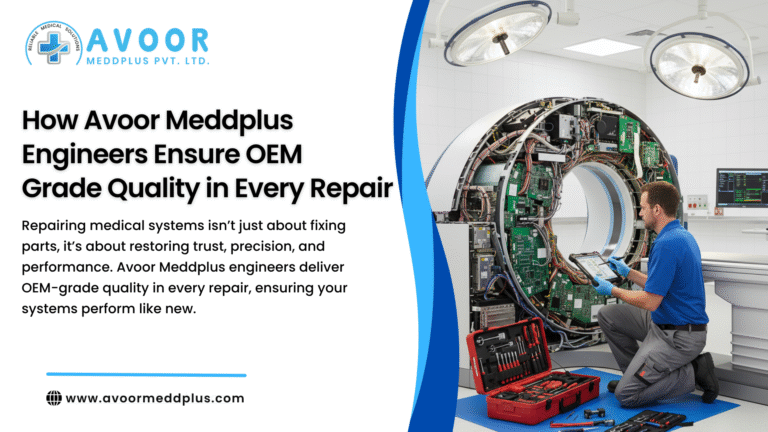

Nuclear medicine imaging systems such as PET/CT and gamma cameras play a critical role in diagnostic accuracy and patient care. Their reliability and performance directly impact image quality, diagnostic confidence, and overall clinical outcomes. Because these systems represent a significant financial investment, consistent and comprehensive maintenance is essential not only for extending equipment lifespan but also for meeting accreditation and regulatory requirements.

At Digirad, our engineers have serviced hundreds of nuclear medicine cameras, witnessing both well-maintained systems and those neglected over time. Based on that experience, we’ve compiled nine expert recommendations to help ensure your gamma camera delivers peak performance for years to come.

1. Establish a Proper Maintenance Schedule

The frequency of preventive maintenance is the foundation of equipment care. Stationary gamma cameras should be serviced twice a year, while mobile imaging systems—exposed to greater wear and tear require at least three maintenance checks annually. It is also wise to schedule a comprehensive service prior to accreditation or physics testing, reducing the risk of downtime during critical inspections.

2. Begin with a Basic Inspection

Every maintenance session should start with the basics. Conduct a visual inspection of the camera, run a test scan, and evaluate its performance. Ensure that mechanical movements are smooth, patient safety mechanisms function correctly, and all cables and wired connections are intact. Small issues such as loose wires can escalate quickly but are easy to correct during early checks.

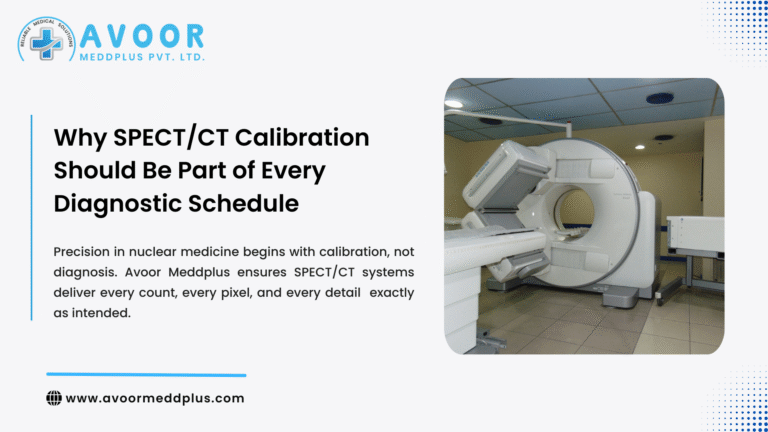

3. Maintain Proper Calibration

Calibration is central to consistent imaging. Industry best practice recommends performing a calibration at least twice a year. During this process, the pixel map is validated, and necessary adjustments are made. A key reminder: whenever a collimator is replaced, the system’s uniformity must be updated to maintain diagnostic accuracy.

4. Manage the Pixel Map Carefully

Bad pixels can significantly degrade image quality. Follow manufacturer guidelines to monitor and maintain the pixel map. Be especially cautious with adjoining bad pixels; eliminating two connected pixels can lead to severe quality issues that compromise clinical interpretation.

5. Keep Software Updated

Modern imaging systems rely heavily on software for processing, security, and compliance. Regularly check for software and security updates to protect sensitive patient information, comply with data protection standards, and ensure continued manufacturer support. Some vendors may refuse to service systems running outdated or unsupported software, making updates essential.

6. Ensure Stable Power Supply

Power irregularities can damage sensitive imaging electronics. Verify that the outlet supplying the gamma camera delivers consistent voltage. If a UPS (Uninterruptible Power Supply) is in use, test its performance to confirm that it will provide backup power during outages. Preventing power-related damage is far less costly than replacing affected components.

7. Prioritize Cleaning and Dust Control

It may seem simple, but cleaning is a vital part of preventive maintenance. Dust accumulation in hospital and clinical environments is common and can lead to overheating and mechanical issues. Regularly clean fans, filters, and other dust-prone areas. Beyond performance, a well-maintained and polished machine also improves patient and staff perception—equipment that looks cared for is treated with greater respect.

8. Perform Regular Database Checks

The database storing imaging studies must be actively managed to avoid corruption and inefficiencies. Schedule monthly backups and purges of older data, ideally keeping no study older than 30 days on the local system. Older cases should be archived to PACS, ensuring that the active database remains stable, secure, and efficient.

9. Maintain a Detailed Service Log

Accurate record-keeping is often overlooked but is crucial. Always update the service logbook with details of inspections, repairs, or parts replaced. While you may remember service details in the short term, having a documented record ensures that long-term trends and recurring issues can be identified—saving time and cost in the future.

Preventive Maintenance Programs: The Smart Investment

While on-demand repairs may seem convenient, preventive maintenance programs offer far greater value. By enrolling in a structured service plan, facilities benefit from:

- Faster response times

- Technical support and troubleshooting

- Priority access to parts and expedited delivery

- Regular software updates

- Reduced labor costs and discounts

Ultimately, these programs are less expensive than reactive repairs, minimizing downtime while ensuring consistent diagnostic reliability.

Final Thoughts: Be Proactive, Not Reactive

Successful nuclear gamma camera maintenance is built on two principles: proactivity and consistency. Waiting until a failure occurs is a costly mistake, both financially and operationally. Preventive care not only extends equipment lifespan but also safeguards patient care standards and regulatory compliance.

By adopting these nine expert strategies, healthcare providers can ensure their imaging systems deliver reliable, high-quality results—maximizing return on investment while providing the best possible patient outcomes.