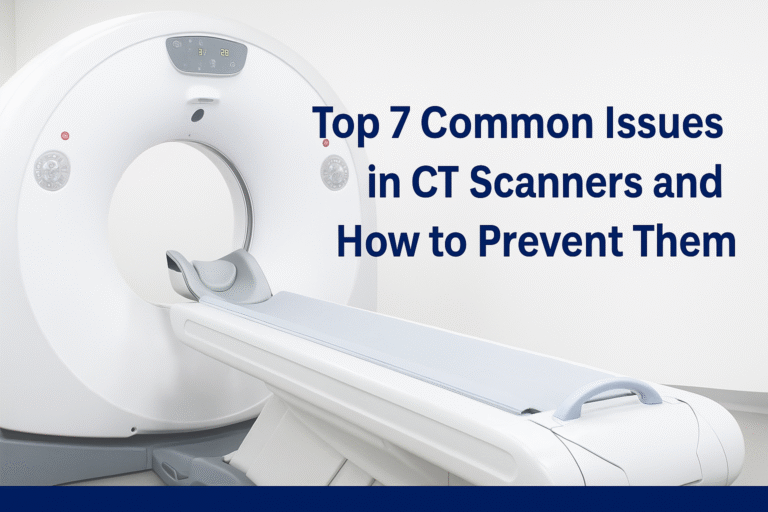

Introduction: The Hidden Cost of CT Scanner Downtime

In modern healthcare, CT scanners play a critical role in fast and accurate diagnostics. They help medical professionals detect conditions such as fractures, tumors, and internal injuries with precision. These systems work continuously in hospitals and diagnostic centers, often scanning dozens of patients every day.

However, even a small technical problem can lead to unexpected downtime. This can disrupt patient schedules, delay critical treatments, and result in a significant financial impact. Most of these problems can actually be avoided with a strong preventive maintenance program.

Below are the top 7 most common CT scanner problems and effective ways to prevent them through proper service and maintenance.

1. Tube Failures and Overheating 🔥

The X-ray tube is the most sensitive and expensive part of a CT scanner. It generates X-rays needed to create cross-sectional images. Continuous use without proper cooling can cause tube overheating or sudden failure.

Common Causes:

- Continuous scanning without adequate cooling intervals

- Inefficient cooling systems

- Ignoring early warning messages

Impact:

Tube failure can cause long periods of downtime and very expensive repairs or replacements.

Prevention Tips:

- Schedule proper cooling cycles during busy hours

- Regularly check cooling fans and heat exchangers

- Monitor tube usage and replace worn-out components on time

2. Image Artifacts and Quality Degradation 🖼️

Image artifacts reduce the clarity of CT images. This affects diagnostic accuracy and patient care. Artifacts like streaks, rings, or blurry images are often warning signs of deeper technical problems.

Common Causes:

- Detector miscalibration

- Tube instability

- Mechanical alignment problems

Impact:

Poor image quality results in repeat scans, increased patient exposure to radiation, and loss of confidence in diagnostic results.

Prevention Tips:

- Conduct regular calibration and quality control tests

- Replace faulty detectors quickly

- Maintain stable power and clean operating conditions

3. Gantry Motor and Bearing Problems ⚙️

The gantry rotates during scanning. If its bearings or motor fail, the entire scan process is affected. Unusual noises or vibrations are early warning signs.

Common Causes:

- Worn bearings

- Poor lubrication

- Dust or debris inside the gantry

Impact:

Mechanical failures in the gantry can lead to major breakdowns if not detected early.

Prevention Tips:

- Lubricate gantry parts as per manufacturer standards

- Keep the scanner room clean and dust free

- Schedule periodic mechanical inspections

4. Power Supply Fluctuations and Hardware Failures ⚡

CT scanners depend on a stable and clean power supply. Voltage drops, surges, or grounding issues can damage internal components.

Common Causes:

- Unstable electrical supply

- No UPS or surge protection

- Poor grounding

Impact:

Sudden power fluctuations can cause system shutdowns and expensive hardware failures.

Prevention Tips:

- Install UPS and stabilizers

- Check grounding regularly

- Monitor power quality and fix issues immediately

5. Software Glitches and System Freezes 🖥️

CT scanners rely heavily on software for image processing and workflow control. Glitches can interrupt scans and delay patient care.

Common Causes:

- Outdated software or firmware

- Corrupted system files

- Network communication issues

Impact:

System freezes or slow performance result in wasted time and delayed reporting.

Prevention Tips:

- Keep software updated with approved patches

- Use stable and secure network connections

- Schedule regular system checks and backups

6. Cooling System Inefficiencies 💧

The cooling system keeps the scanner’s internal components at safe operating temperatures. If it fails, the entire system is at risk.

Common Causes:

- Clogged filters or blocked fans

- Low coolant levels

- Malfunctioning chillers or pumps

Impact:

Poor cooling increases the chance of tube failure and shortens equipment lifespan.

Prevention Tips:

- Clean filters and fans regularly

- Maintain proper coolant levels

- Include chiller inspection in every maintenance cycle

7. Detector Malfunctions 🧲

Detectors convert X-rays into digital signals. Faulty detectors result in poor image quality and unreliable results.

Common Causes:

- Dust, humidity, or static electricity

- Faulty detector modules

- Calibration drift

Impact:

Detector issues lead to poor scan quality and increase operating costs due to re-scans.

Prevention Tips:

- Keep the scanner room clean and humidity controlled

- Calibrate detectors periodically

- Replace or repair damaged modules quickly

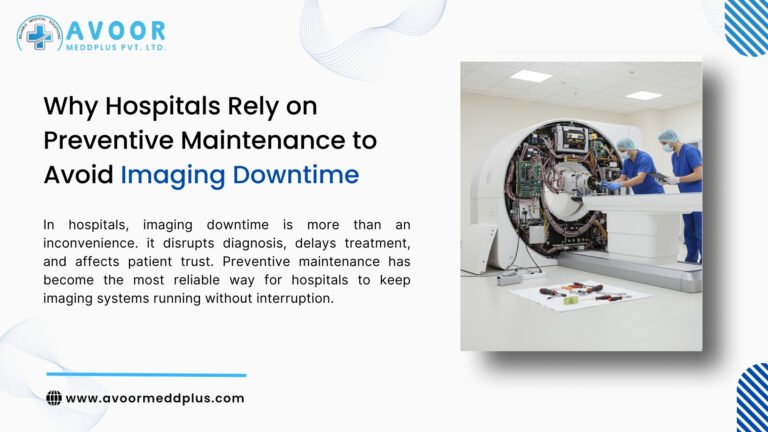

Why Preventive Maintenance is the Best Solution 🧰

Most CT scanner issues do not happen suddenly. They start as small, unnoticed faults that grow over time. A structured preventive maintenance program can identify and fix these problems early.

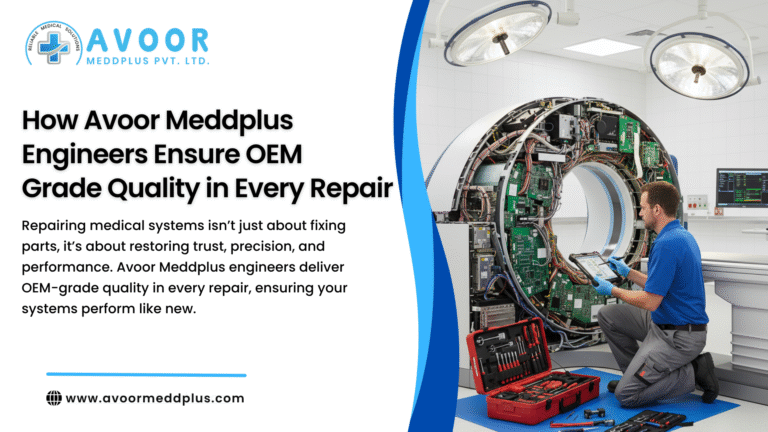

At Avoor Meddplus, our ISO 13485 certified service team follows a proven preventive maintenance process. This includes:

- Complete component inspection and calibration

- Software and firmware updates

- Cooling system servicing and power checks

- Environmental and safety audits

Regular preventive maintenance helps hospitals and diagnostic centers avoid unexpected downtime, extend equipment life, and maintain image quality.

Conclusion: Prevention is Smarter than Repair

CT scanner failures can cause more than just repair bills. They delay patient care, increase costs, and affect reputation. By understanding these seven common issues and taking preventive action, healthcare facilities can keep their systems running smoothly.

Partnering with a trusted service provider like Avoor Meddplus ensures your CT scanners stay reliable, efficient, and fully compliant with quality standards.

Get Reliable Medical Equipment Repair and Service Support

If you have any repair service requirements, contact us today.

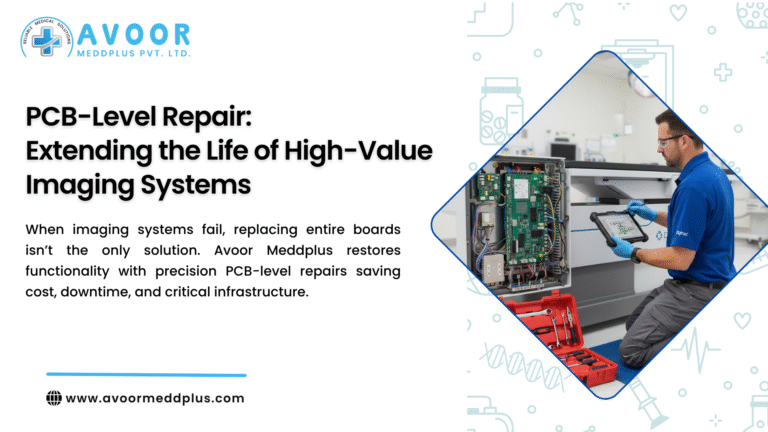

We have a team of experienced engineers who can repair a wide range of medical imaging equipment quickly and efficiently.

We have branches in Chennai, Mumbai, Hyderabad, and Bangalore, and we provide service support worldwide.

We offer not only repair services but also AMC, CAMC, and per-call service support, tailored to meet the needs of hospitals, diagnostic centers, and healthcare facilities of all sizes.

We provide repair and maintenance support for popular models including:

- CT Scanners: GE Discovery, Philips Brilliance, Siemens Somatom, Toshiba Aquilion, and more

- DR and C-ARM Systems: Siemens Ysio Max, GE Definium, Philips DigitalDiagnost, and more

- Mammography Systems: Hologic Selenia, Fujifilm Amulet, and more

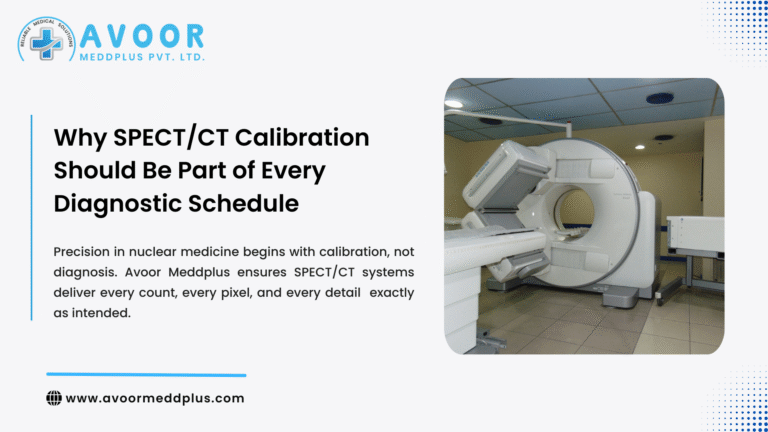

- Nuclear Medicine Equipment: GE Infinia Hawkeye, Philips BrightView, Mediso AnyScan, and more

Reach out to Avoor Meddplus for reliable service, fast turnaround, and expert technical support.