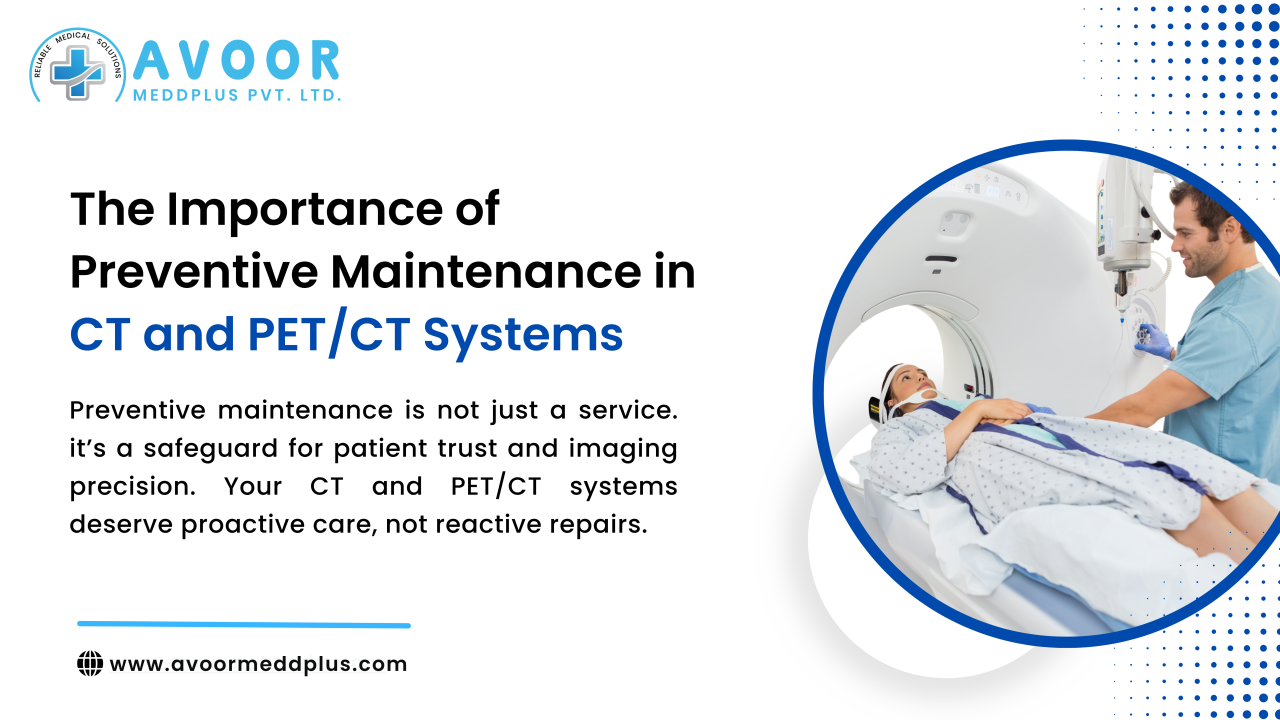

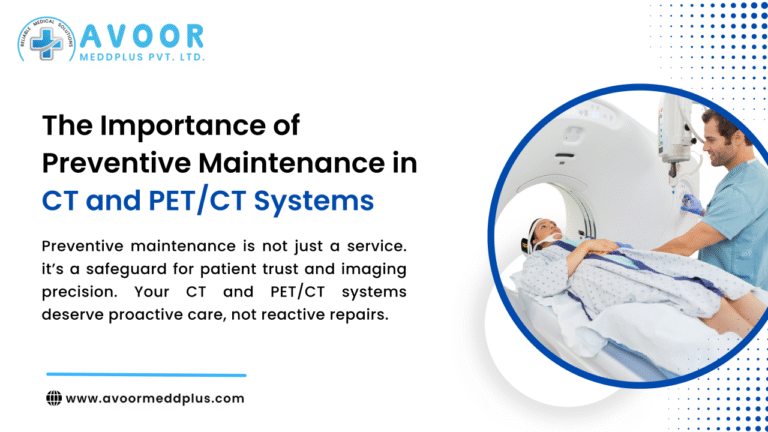

1. Understanding Preventive Maintenance in Imaging Systems

Preventive maintenance ensures CT and PET/CT systems operate flawlessly. It involves periodic inspections, calibrations, and performance verifications. Technicians identify minor faults before they escalate into major breakdowns. Proper upkeep extends the equipment lifespan significantly. It guarantees consistent imaging accuracy and patient safety. Scheduled servicing reduces costly emergency repairs. In essence, preventive care is the backbone of reliable diagnostics.

2. The Financial Value of Routine Equipment Care

Preventive maintenance isn’t just a technical process—it’s financial wisdom. Regular servicing minimizes unscheduled downtime and revenue loss. Hospitals save on emergency repair and replacement expenses. Efficient equipment supports more scans, increasing daily throughput. Insurance and warranty claims become smoother with maintenance records. Better ROI is achieved through asset optimization and reliability. Every rupee spent on prevention saves multiples in recovery costs.

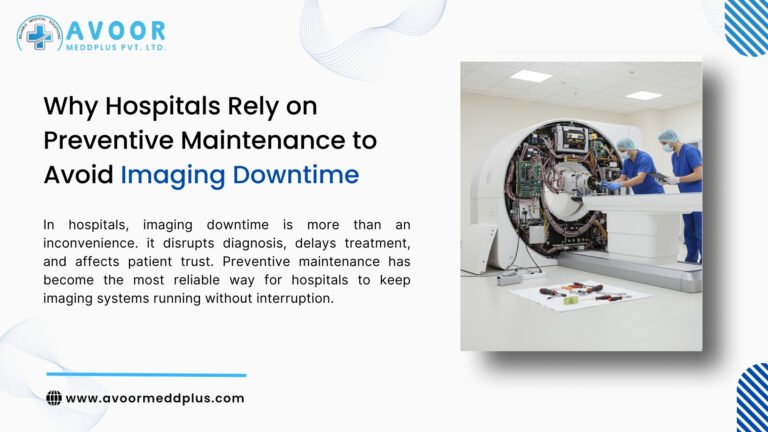

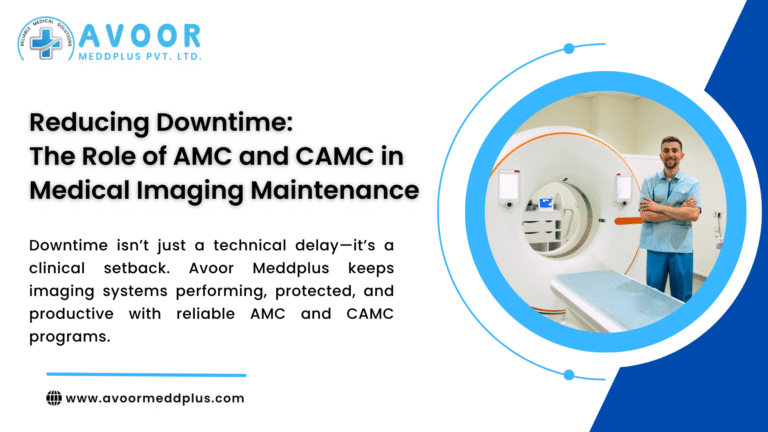

3. Uptime: The Key Metric in Diagnostic Imaging

System uptime defines a facility’s ability to serve patients efficiently. Even minor downtime can disrupt hospital schedules and workflows. Preventive maintenance keeps machines operating at peak efficiency. Routine inspections detect worn parts before failure occurs. Backup checks ensure continuity in emergency situations. Maximum uptime builds trust among clinicians and patients. Maintenance translates directly to consistent operational excellence.

4. Image Quality and Diagnostic Accuracy

A well-maintained CT or PET/CT scanner ensures crystal-clear imaging. Calibrated systems produce accurate diagnostic results every time. Image artifacts caused by neglect can mislead clinical interpretations. Routine calibrations maintain uniformity across scan sessions. Technicians assess detectors, gantry movements, and cooling systems. Consistent quality improves radiologist confidence and efficiency. Ultimately, preventive care enhances diagnostic precision.

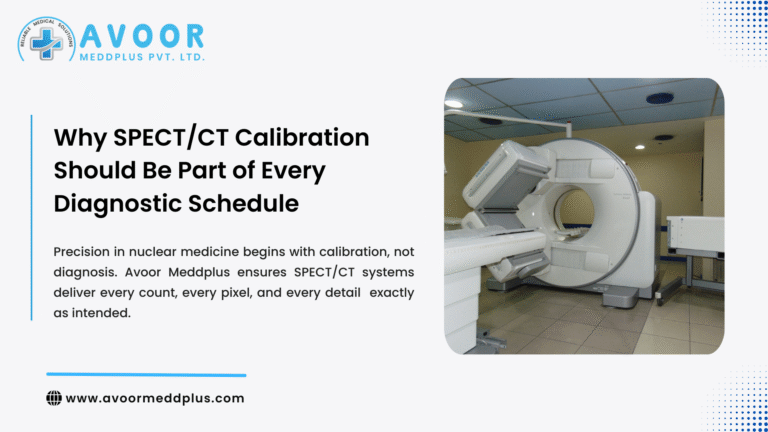

5. Reducing Radiation Exposure and Risk

Preventive maintenance helps control radiation output precisely. Faulty detectors or calibration errors can increase dose exposure. Routine testing ensures compliance with radiation safety standards. Technicians verify shielding, sensors, and dose control units. Maintained systems protect both patients and operators alike. Regulatory audits become smoother with updated maintenance logs. Safety is not optional—it’s built through proactive maintenance.

6. Extending Equipment Lifespan and ROI

CT and PET/CT scanners represent substantial capital investments. Without maintenance, their efficiency declines prematurely. Regular servicing protects critical components from wear and damage. Cooling systems, detectors, and power modules remain stable longer. A consistent service schedule boosts return on investment (ROI). Lifecycle management becomes predictable and cost-efficient. Longevity results from systematic, professional care routines.

7. Preventing Unplanned Downtime

Sudden breakdowns lead to major operational disruptions. Preventive checks detect early warning signs in hardware or software. Firmware updates keep systems compatible and responsive. Technicians address performance drifts before they escalate. Emergency calls and patient reschedules are drastically reduced. Predictability in maintenance boosts hospital efficiency metrics. A stitch in time truly saves nine in imaging service operations.

8. Enhancing Patient Experience and Trust

Reliable scanners foster smoother patient experiences. Minimal delays and faster results increase satisfaction. Accurate imaging reduces the need for repeat scans. Technicians can focus on patient care instead of equipment issues. Trust grows when hospitals deliver consistent service quality. Brand reputation improves through reliability and performance. Preventive maintenance builds a foundation for patient loyalty.

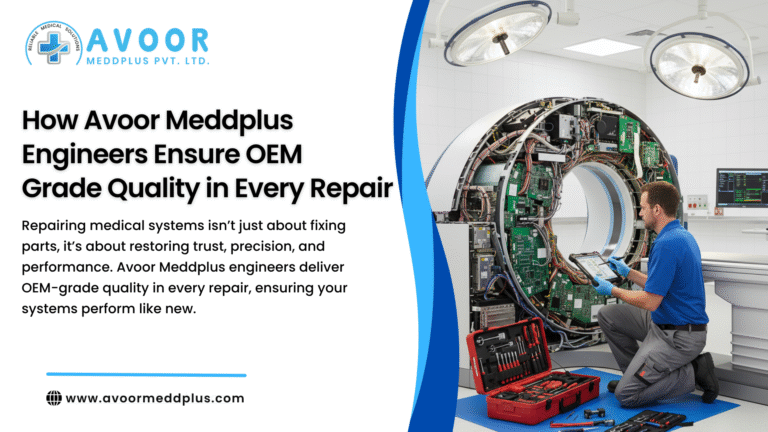

9. The Role of Qualified Service Engineers

Certified service engineers bring technical depth and precision. They perform performance validation and detailed system diagnostics. Factory-trained expertise ensures manufacturer-grade standards. Skilled engineers use advanced calibration tools and analytics. Proper training leads to fewer errors and faster issue resolution. Strong service teams build trust between vendors and clients. Human expertise remains central to reliable machine performance.

10. Data-Driven Maintenance Scheduling

Modern imaging systems generate detailed performance data. Predictive analytics can forecast potential issues in advance. IoT-based monitoring supports data-driven maintenance planning. Alerts trigger inspections when parameters cross safe thresholds. This proactive model reduces unnecessary service visits. Avoor Meddplus leverages such intelligence in its workflows. Data transforms maintenance from reactive to strategic.

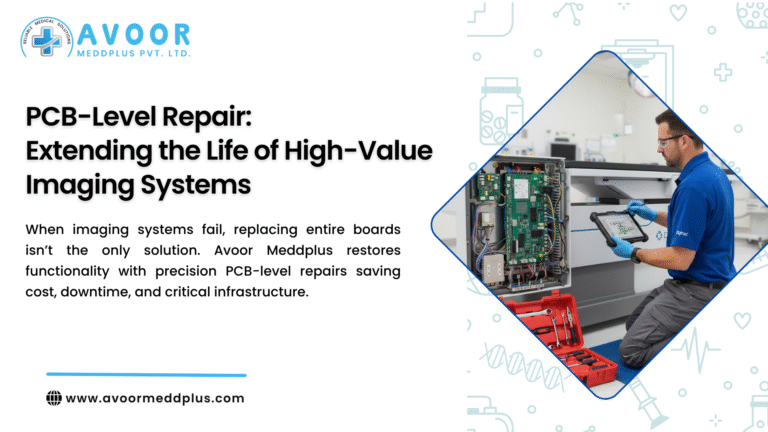

11. Importance of Vendor-Approved Components

Only certified components guarantee safety and compatibility. Unauthorized parts can disrupt imaging quality or void warranties. Preventive maintenance ensures authentic replacements are used. Original parts maintain equipment reliability and precision. Proper sourcing supports long-term system stability. Vendor relationships simplify part logistics and approvals. Quality materials lead to consistent diagnostic performance.

12. Regulatory Compliance and Documentation

Preventive maintenance supports compliance with regulatory norms. Audit trails demonstrate adherence to safety and performance standards. Updated service logs aid during accreditation or inspections. Traceability ensures accountability at every maintenance stage. Medical boards require consistent documentation for transparency. Well-documented maintenance boosts institutional credibility. Compliance today prevents penalties tomorrow.

13. Technological Upgrades and Firmware Updates

System firmware often evolves to enhance imaging features. Regular updates improve functionality and bug resilience. Preventive maintenance includes reviewing version control logs. Technicians install patches and recalibrate software parameters. Up-to-date systems deliver optimal workflow integration. Enhanced UI and automation improve technician productivity. Upgrades keep devices aligned with modern clinical demands.

14. Training and Knowledge Transfer

Preventive maintenance isn’t just mechanical—it’s educational. On-site staff learn safe handling and early issue detection. Knowledge sharing improves overall equipment care culture. Hands-on training builds self-reliance in hospitals. Operators learn calibration awareness and proper usage cycles. Well-informed teams reduce dependency on emergency service calls. Avoor Meddplus emphasizes skill-based training initiatives.

15. Environmental Impact of Maintenance Practices

Efficient machines consume less energy and resources. Preventive care reduces e-waste and extends component life. Optimal cooling and calibration minimize electricity usage. Recycling and reuse of parts lower environmental footprints. Avoor Meddplus promotes eco-conscious maintenance routines. Sustainability in healthcare improves public image and savings. Green maintenance is smart, ethical, and efficient.

16. Digital Maintenance Logs and Recordkeeping

Digital systems simplify tracking and scheduling tasks. Cloud-based logs make data accessible to service teams. Instant access accelerates maintenance verification. Transparency improves with time-stamped maintenance reports. Data analytics reveal trends in system performance decline. Automation reduces paperwork and manual errors. Smart logging defines the future of MedTech maintenance.

17. Integrating Predictive Maintenance Models

Predictive maintenance uses real-time data analytics. AI predicts part failures before they interrupt operation. CT and PET/CT uptime improves through proactive scheduling. This reduces emergency service and part replacements. Avoor Meddplus employs predictive insights across networks. It minimizes downtime and maximizes performance consistency. Predictive systems represent the next evolution in maintenance.

18. Avoor Meddplus: Elevating Imaging Reliability

Avoor Meddplus offers specialized CT and PET/CT maintenance. Its experts deliver precision diagnostics and on-site calibration. Comprehensive AMC plans minimize downtime across India. The company’s preventive programs ensure imaging consistency. Clients enjoy faster service response and verified quality. Every contract aligns with OEM standards and safety norms. Avoor Meddplus defines reliability through preventive excellence.

19. Advanced Tools and Techniques at Avoor Meddplus

Avoor Meddplus engineers utilize state-of-the-art test equipment. From detector calibration to system tuning—they cover it all. Each service visit includes quality assurance and documentation. Their predictive systems use real-time performance analytics. Clients receive performance dashboards and maintenance reports. Proactive solutions replace reactive service culture. This ensures unmatched operational continuity for hospitals.

20. Avoor Meddplus: Your Partner in Imaging Excellence

Avoor Meddplus stands as a trusted partner for healthcare facilities. Its preventive maintenance programs protect capital investments. Comprehensive care plans improve uptime and patient throughput. Skilled engineers and quick response form its service DNA. Hospitals across India trust Avoor Meddplus for reliability. Every scan reflects precision, safety, and performance excellence. Choose Avoor Meddplus — where care meets technology.

Conclusion

Preventive maintenance is the heartbeat of reliable imaging systems. It safeguards investment, ensures patient safety, and enhances diagnostic precision. Through data-driven strategies, certified engineering, and consistent calibration, CT and PET/CT systems achieve maximum uptime and performance. Avoor Meddplus exemplifies this commitment, offering nationwide support and innovative maintenance models. Preventive care today builds diagnostic confidence for tomorrow.

GE HealthCare India Siemens Healthineers Siemens Philips Wipro Trivitron Healthcare Allengers Global Healthcare Pvt. Ltd. BPL Medical Technologies FUJIFILM Philippines Medical Systems Canon EMEA Skanray Technologies