Introduction

Mammography systems are among the most precision-dependent diagnostic tools in medical imaging. Even the smallest calibration drift or component failure can affect image clarity and lead to diagnostic uncertainty. At Avoor Meddplus, we specialize in restoring precision in mammography equipment through advanced repair techniques, OEM-standard calibration, and thorough component testing ensuring reliable, accurate imaging for early breast cancer detection.

1. Understanding the Importance of Precision in Mammography

Mammography requires sub-millimeter accuracy and consistent grayscale uniformity. The slightest deviation in detector sensitivity or tube output can compromise diagnostic results. Maintaining precision is not just technical. it’s clinical, directly influencing patient outcomes.

2. Common Issues Affecting Mammography Equipment

- Detector calibration drift

- X-ray tube aging or anode pitting

- AEC (Automatic Exposure Control) malfunctions

- Software errors in image reconstruction

- Mechanical misalignments in compression paddles or gantry

Each of these issues demands expert-level inspection and repair to restore accuracy and safety.

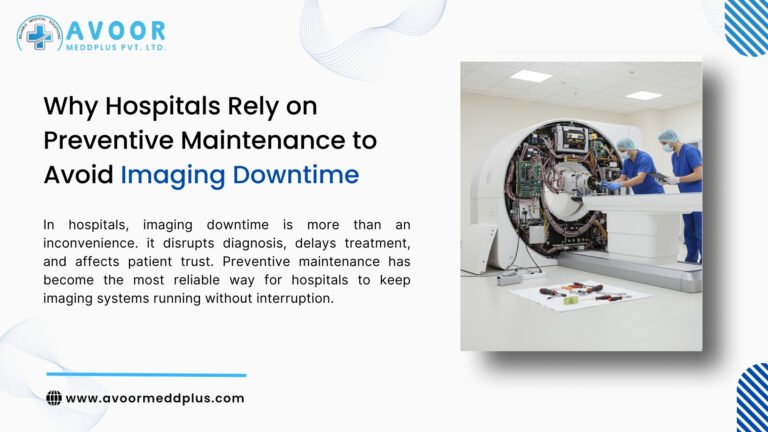

3. The Initial Inspection and Diagnosis

Our repair process begins with a comprehensive system diagnosis. Engineers review service logs, perform mechanical checks, analyze image artifacts, and verify exposure consistency. This helps identify both surface-level and underlying issues before any part replacement.

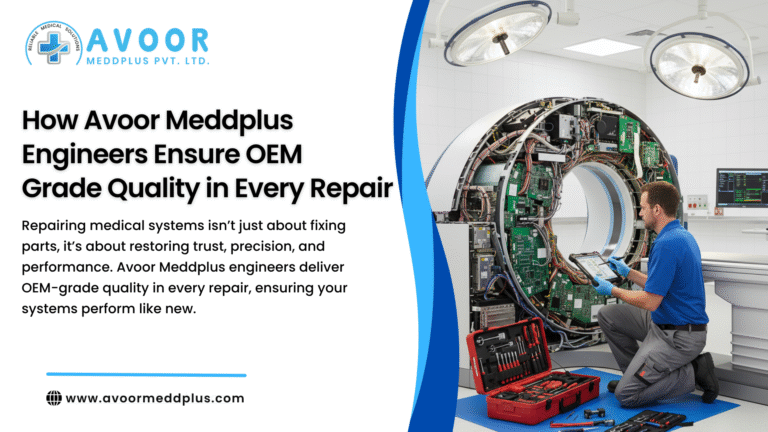

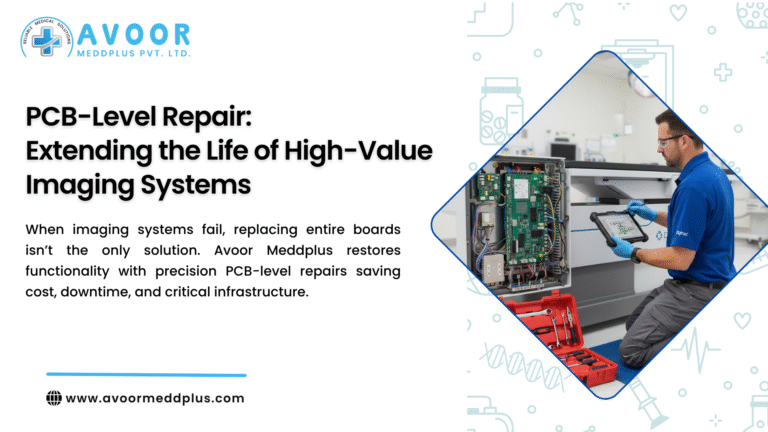

4. Component-Level Repair and Replacement

Avoor Meddplus engineers are trained in board-level and detector-level repair for mammography systems. We service:

- Power boards and HV generators

- Detector modules and AEC sensors

- Control PCBs and firmware systems

- Tube assemblies and cooling systems

Each repair follows OEM-approved procedures to ensure system reliability.

5. Precision Calibration and Quality Assurance

Post-repair, every mammography unit undergoes calibration and image uniformity testing using industry-standard phantoms. Our calibration process ensures:

- Uniform grayscale response

- Accurate contrast and sharpness levels

- Balanced AEC performance

- Alignment verification for gantry and detector plane

These steps ensure diagnostic-grade accuracy comparable to new systems.

6. Software and Firmware Validation

Software mismatches often cause image inconsistencies or communication faults. Our engineers verify firmware versions, synchronize detector and control system parameters, and ensure complete software integration before final certification.

7. Safety and Compliance Testing

All repaired mammography systems undergo radiation safety checks and mechanical movement validation to comply with AERB and OEM standards. We also perform compression mechanism testing for consistent, safe patient operation.

8. Post-Repair Quality Validation

Before system handover, Avoor Meddplus conducts:

- Image quality evaluation

- Noise and distortion testing

- System warm-up and endurance run

- Service documentation and calibration certificate issuance

Every repaired system leaves our facility fully validated, ensuring diagnostic readiness from day one.

9. Benefits of Expert Mammography Repair

- Restores OEM-level precision and image clarity

- Extends equipment lifespan

- Reduces downtime and operational loss

- Maintains compliance with safety standards

- Saves costs versus full equipment replacement

10. Why Choose Avoor Meddplus

- Specialized engineers for mammography and digital breast imaging systems

- In-house component-level repair labs

- Advanced calibration tools and testing setups

- OEM-standard protocols with warranty coverage

- Nationwide on-site service and support

Conclusion

The precision of mammography equipment defines the quality of breast cancer screening and diagnosis. Through a structured, expert-led repair process, Avoor Meddplus restores complete system functionality from component replacement to calibration and compliance testing. Our mission is to ensure that every scan delivers diagnostic confidence, accuracy, and safety helping healthcare providers maintain excellence in women’s imaging services.