Introduction

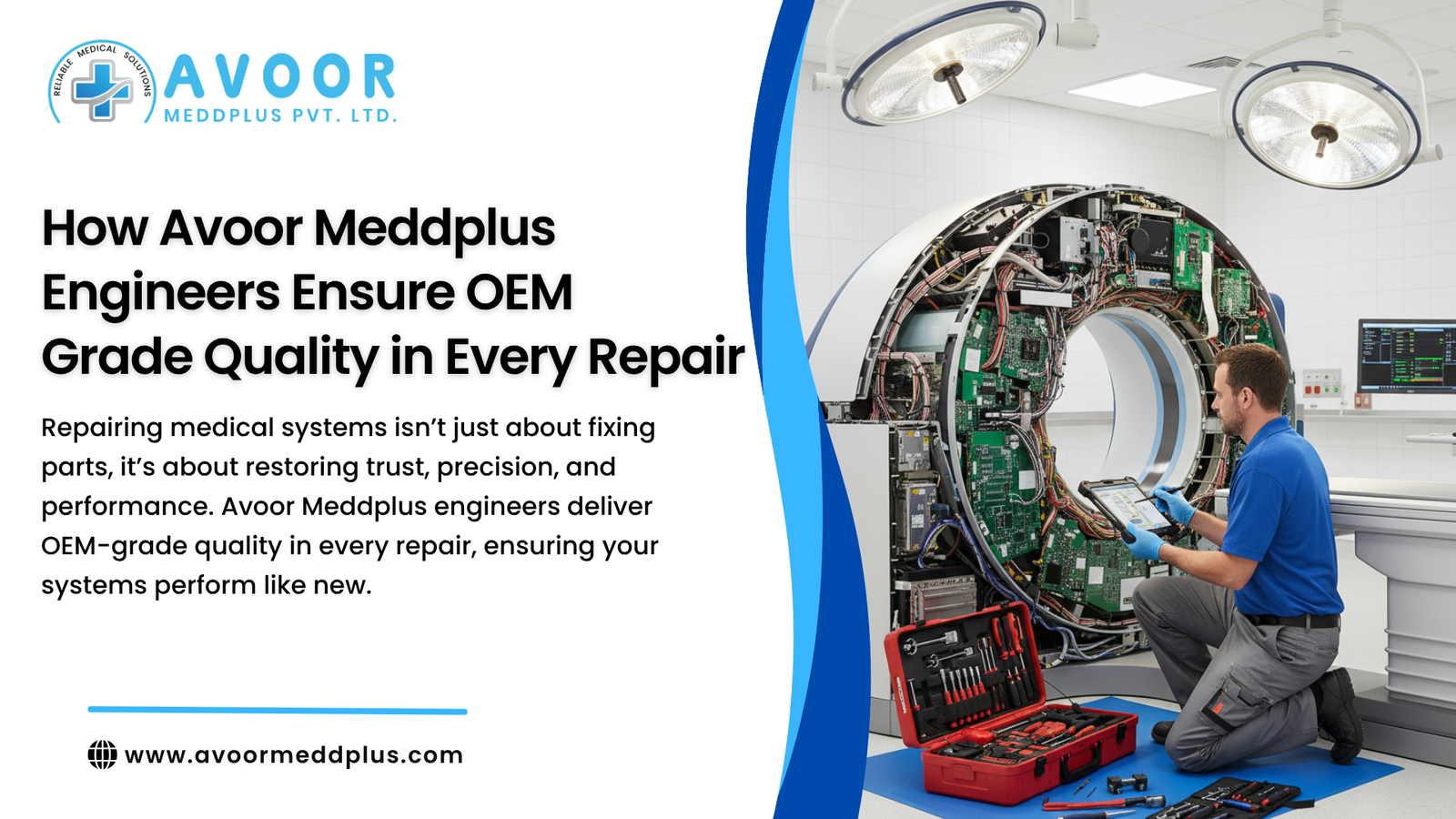

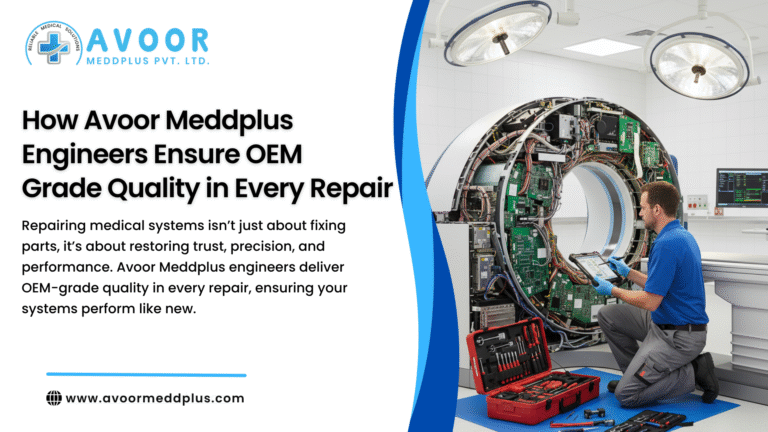

At Avoor Meddplus, every OEM-grade quality repair follows factory-level testing and calibration protocols. In the world of diagnostic imaging, precision and reliability define patient safety. Every scan, calibration, and image reconstruction depends on the flawless performance of complex equipment from CT and MRI systems to PET/CT and DR detectors. When a breakdown occurs, quality of repair matters as much as speed.

That’s why Avoor Meddplus stands apart. Our engineers don’t just fix faults, they restore every system to OEM-grade performance, ensuring safety, accuracy, and long-term reliability that meet original manufacturer standards.

The secret lies in our OEM-driven repair protocols, state-of-the-art testing infrastructure, and deep understanding of biomedical electronics.

1. What OEM-Grade Repair Really Means

The term OEM-grade quality goes beyond using genuine parts. It represents adherence to the same engineering principles, calibration accuracy, and testing methodology that equipment manufacturers use during production and quality checks.

For Avoor Meddplus engineers, this means:

- Using original components or manufacturer-approved equivalents

- Following OEM schematics and service documentation

- Performing multi-stage validation tests after repair

- Documenting every step for traceability and compliance

This approach ensures that repaired systems perform just as efficiently and safely as when they left the factory.

2. The Avoor Meddplus Repair Process Step by Step

Our repair process is designed around OEM standards and executed by certified biomedical engineers.

1️⃣ Detailed Fault Diagnosis:

Every device undergoes a structured inspection, including board-level analysis, component testing, and software error log review.

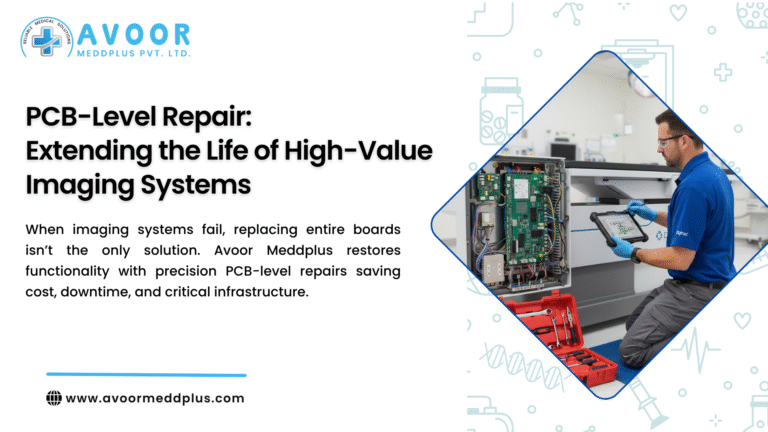

2️⃣ Component-Level Repair:

We repair down to the PCB and microcircuit level, replacing damaged ICs, capacitors, and connectors using advanced soldering and ESD-safe tools.

3️⃣ OEM-Grade Parts & Materials:

Only genuine or OEM-certified replacement components are used, ensuring compatibility and performance.

4️⃣ Calibration & Alignment:

After repair, the system is calibrated using OEM-specified calibration kits to restore imaging accuracy.

5️⃣ Quality Assurance Testing:

Every system passes through functional verification, load simulation, and image quality validation before returning to service.

Through these five steps, Avoor Meddplus achieves a level of precision and consistency that matches OEM service standards.

3. Engineering Excellence Behind Every Repair

Our engineering team is the core strength of Avoor Meddplus. Each technician is trained in:

- Electronic board diagnostics and micro-soldering

- Firmware restoration and DICOM configuration

- Power and signal integrity testing

- Radiation safety validation (AERB standards)

By combining electronics expertise with medical technology experience, our engineers handle every repair with precision and accountability.

4. 5 Expert Reasons Why OEM-Grade Repairs Deliver More Value

1️⃣ Performance Reliability: Restored systems maintain imaging precision, power efficiency, and software stability.

2️⃣ Extended Equipment Life: OEM-grade parts and calibration reduce recurring failures.

3️⃣ Regulatory Compliance: Repairs align with AERB and NABH maintenance guidelines.

4️⃣ Safety Assurance: Radiation levels, grounding, and electrical insulation are verified per OEM safety norms.

5️⃣ Cost Efficiency: Facilities save 40–60% over OEM service costs without compromising on quality.

OEM-grade quality is not about lowering cost — it’s about maintaining engineering integrity while optimizing service value.

5. Advanced Tools and Testing Infrastructure

Avoor Meddplus maintains a full-fledged repair and calibration lab equipped with:

- Oscilloscopes, digital multimeters, and signal analyzers

- Thermal imaging systems for board-level heat detection

- ESD-protected rework stations for component safety

- OEM calibration tools and software for alignment tests

This ensures that every repaired device undergoes the same scrutiny and quality control as an OEM-manufactured product.

6. Compliance and Documentation

Each repair and calibration process is documented in line with AERB and ISO 13485 service documentation standards.

👉 Reference: AERB – Safety Standards for Medical Equipment

(Outbound link ensures SEO authority and compliance)

Every job report includes component traceability, test results, and compliance certification — providing clients with complete transparency and audit readiness.

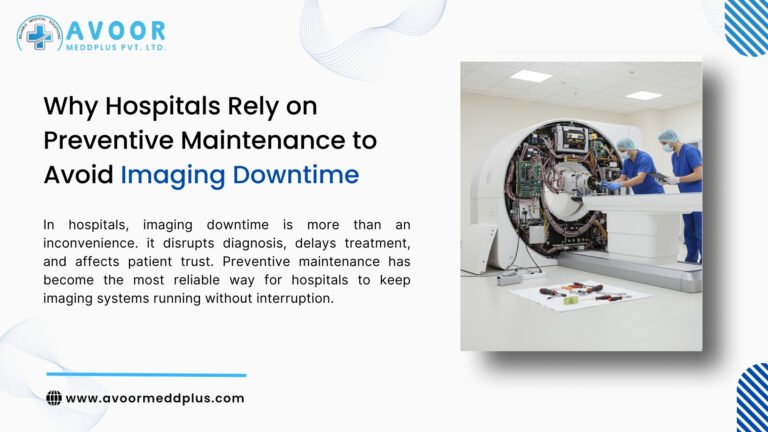

7. Beyond Repairs: Preventive Maintenance and Lifecycle Care

OEM-grade repair is only one part of the Avoor Meddplus service ecosystem. We also provide:

- AMC (Annual Maintenance Contracts) for periodic servicing

- CAMC (Comprehensive Contracts) covering parts and labor

- Per-Call Repair Services for emergency support

By combining these with board-level repair expertise, we extend equipment life and reduce total cost of ownership ensuring that healthcare facilities remain operational, compliant, and profitable.

8. Why Avoor Meddplus Is Trusted Nationwide

- Certified engineers with 10+ years of medical electronics experience

- Genuine component sourcing and part-level documentation

- OEM-calibrated test and measurement tools

- Fast turnaround time and on-site service coverage

- Proven record of >98% uptime for supported systems

When healthcare providers choose Avoor Meddplus, they choose reliability, precision, and trust — the three pillars of OEM-grade quality.

Conclusion

Delivering OEM-grade quality in every repair is not just a promise, it’s the foundation of Avoor Meddplus service philosophy. Every repair follows the same discipline and technical excellence as the original manufacturer, ensuring your imaging systems operate safely, accurately, and efficiently.

From PCB-level restoration to software calibration, Avoor Meddplus engineers redefine what true quality repair means helping hospitals and imaging centers achieve long-term reliability and maximum uptime.