Introduction

Medical imaging and diagnostic equipment play a critical role in patient care, clinical decision-making, and hospital efficiency. From CT and PET/CT systems to DR, C-ARM, and nuclear medicine equipment, every device must operate with precision and safety. At the center of this responsibility are certified biomedical engineers, whose expertise directly impacts equipment safety, reliability, and compliance.

The importance of certified biomedical engineers equipment safety has grown significantly as modern imaging systems become more complex, software-driven, and regulation-intensive. At Avoor Meddplus, certified biomedical engineers ensure that every system delivers accurate performance while meeting OEM and regulatory standards.

This blog explains how certified biomedical engineers protect equipment safety and why their role is essential for every healthcare facility.

1. Certified Biomedical Engineers Equipment Safety – Why It Matters

Certified biomedical engineers are trained to understand both the clinical application and the technical architecture of medical equipment. Their role goes far beyond basic repairs. They ensure that every system operates within defined safety parameters, protecting patients, clinicians, and hospital infrastructure.

Without certified expertise, even minor technical errors can result in:

- Incorrect diagnostic results

- Unsafe radiation exposure

- Equipment instability or frequent breakdowns

- Non-compliance during audits

This is why certified biomedical engineers equipment safety is the foundation of dependable healthcare technology.

2. Ensuring Compliance with Safety and Regulatory Standards

Healthcare equipment must comply with strict safety regulations, including radiation control, electrical safety, and performance validation. Certified biomedical engineers are trained to follow national and international guidelines during installation, calibration, and maintenance.

Their responsibilities include:

- Radiation output verification

- Electrical grounding and leakage testing

- Calibration documentation

- Quality control reporting

- Audit readiness for NABH and AERB inspections

By maintaining compliance, biomedical engineers ensure equipment safety and help facilities avoid regulatory risks.

3. 5 Expert Ways Certified Biomedical Engineers Ensure Safe Equipment Performance

1️⃣ OEM-Grade Calibration and Validation

Certified biomedical engineers follow manufacturer-recommended calibration procedures. This ensures:

- Accurate image output

- Correct dose delivery

- Stable system performance

OEM-grade calibration is critical for maintaining diagnostic accuracy and preventing long-term system drift.

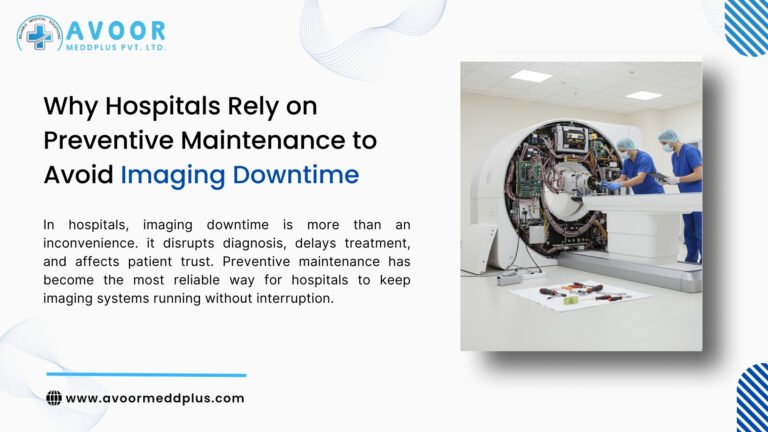

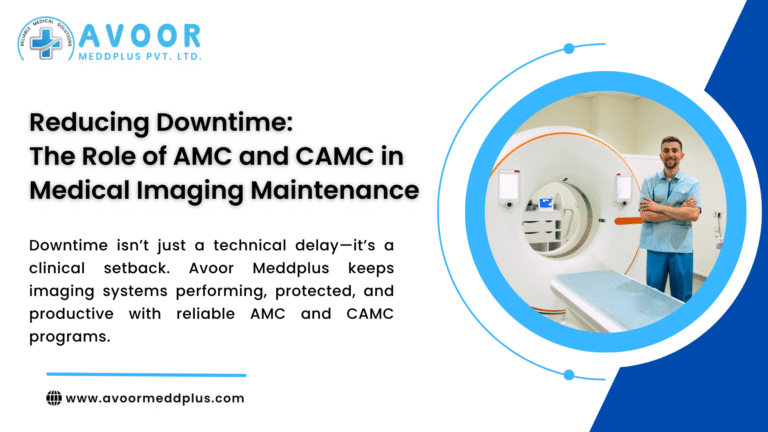

2️⃣ Preventive Maintenance for Safety Assurance

Preventive maintenance is a key responsibility of certified biomedical engineers. Through scheduled inspections, they identify potential risks before failures occur.

Preventive safety checks include:

- Power supply stability testing

- Cooling and ventilation assessment

- Detector health evaluation

- Mechanical alignment verification

This proactive approach significantly reduces safety incidents and unexpected downtime.

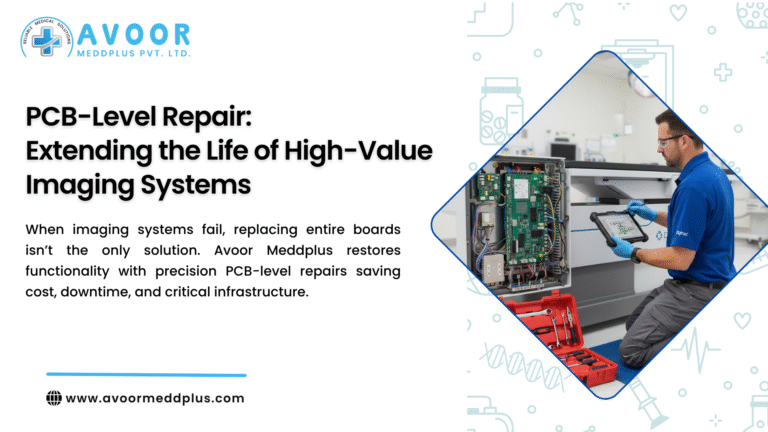

3️⃣ PCB-Level Diagnostics and Repair

Modern medical equipment relies heavily on complex electronic boards. Certified biomedical engineers trained in PCB-level diagnostics can detect micro-faults that affect safety and performance.

This expertise helps:

- Prevent cascading hardware failures

- Restore stable signal and power flow

- Reduce dependency on complete board replacements

Board-level repair ensures long-term safety while optimizing maintenance costs.

4️⃣ Radiation and Electrical Safety Testing

Equipment safety is not limited to image quality. Certified biomedical engineers routinely perform:

- Radiation leakage checks

- KV/mA output validation

- Electrical insulation and grounding tests

These safety tests protect patients, radiologists, surgeons, and technical staff from unnecessary exposure and electrical hazards.

5️⃣ Accurate Documentation and Traceability

Certified biomedical engineers maintain detailed service records, calibration certificates, and safety reports. This documentation is critical for:

- Regulatory compliance

- Hospital audits

- Risk management

- Long-term performance tracking

Well-documented maintenance history ensures transparency and accountability in equipment safety.

4. Role of Certified Engineers Across Imaging Modalities

Certified biomedical engineers support safety across all diagnostic systems, including:

CT & PET/CT Systems

- Gantry alignment and detector calibration

- Radiation dose verification

- Cooling and power system checks

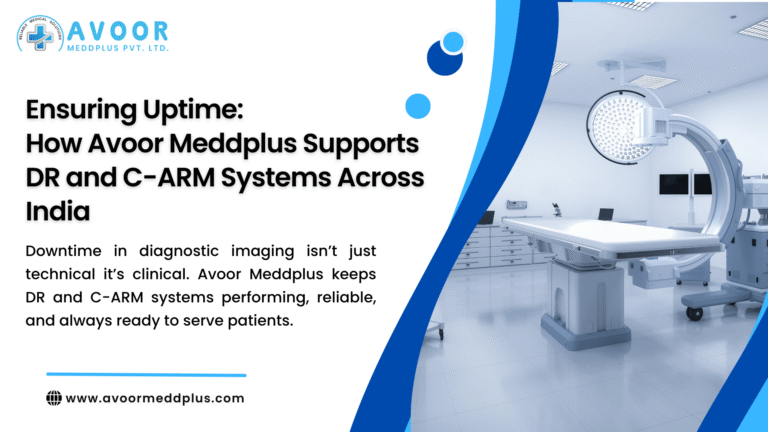

DR & CR Systems

- Flat-panel detector uniformity

- Exposure accuracy testing

- Image consistency validation

C-ARM Systems

- Fluoroscopy output safety

- Mechanical stability checks

- Radiation dose control

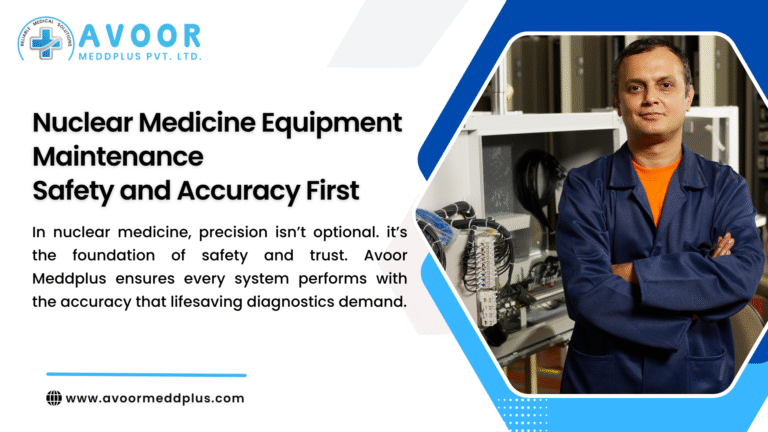

SPECT/CT & Nuclear Medicine

- Energy peaking and uniformity

- Fusion accuracy

- Safety compliance for radionuclide imaging

Across every modality, certified expertise ensures consistent and safe operation.

5. Why Equipment Safety Depends on Certified Expertise

Uncertified handling or improper service practices can compromise safety in multiple ways:

- Calibration errors leading to inaccurate diagnosis

- Increased radiation exposure

- Repeated equipment failures

- Loss of clinical confidence

6. How Avoor Meddplus Strengthens Equipment Safety

At Avoor Meddplus, certified biomedical engineers deliver comprehensive safety-focused services, including:

- OEM-grade calibration and validation

- Preventive maintenance programs

- PCB-level repair and diagnostics

- Fast-response breakdown support

- Safety testing and compliance documentation

- Nationwide service coverage

By combining technical depth with clinical understanding, Avoor Meddplus ensures safe, reliable, and compliant equipment performance for healthcare facilities across India.

Conclusion

The role of certified biomedical engineers equipment safety cannot be overstated in modern healthcare environments. As diagnostic systems become more advanced, the margin for error becomes smaller. Certified biomedical engineers ensure that equipment performs safely, accurately, and consistently protecting patients, clinicians, and hospital operations.

With expert calibration, preventive maintenance, and safety-focused engineering, Avoor Meddplus stands as a trusted partner in delivering secure and reliable medical equipment performance across all imaging modalities.