Introduction

Medical imaging equipment such as CT, PET/CT, DR, C-ARM, SPECT/CT, and mammography systems are the backbone of modern diagnostics. Their accuracy, uptime, and safety directly affect patient outcomes and hospital efficiency. However, maintaining these complex systems is not without difficulty.

Across hospitals and diagnostic centers, medical imaging equipment maintenance challenges continue to impact workflow, compliance, and long-term equipment performance. Without a structured approach, these challenges lead to frequent downtime, rising repair costs, and compromised diagnostic accuracy.

At Avoor Meddplus, these challenges are addressed through preventive maintenance, OEM-grade calibration, and expert biomedical engineering support. Below are the 7 most critical challenges in medical imaging equipment maintenance — and practical solutions to overcome them.

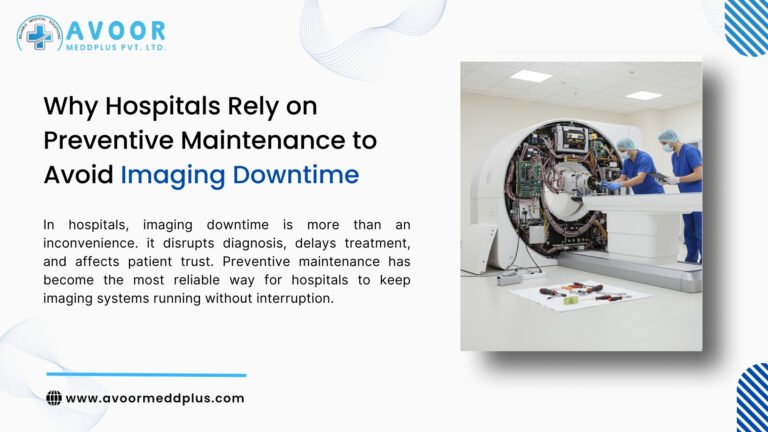

1. Unplanned Equipment Downtime

One of the most common medical imaging equipment maintenance challenges is unexpected downtime. Sudden failures disrupt patient schedules, delay diagnosis, and reduce revenue.

Why it happens

- Lack of preventive maintenance

- Ignored early warning signs

- Aging components

How to solve it

- Implement scheduled preventive maintenance

- Monitor system error logs regularly

- Perform early component health checks

A preventive approach can reduce unplanned downtime by more than 60%.

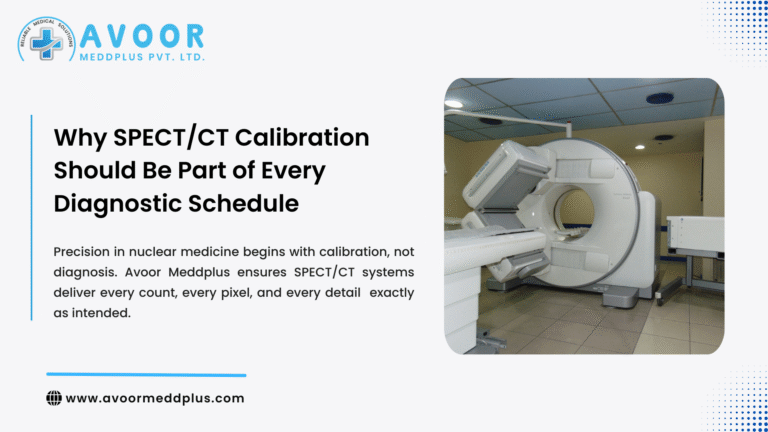

2. Calibration Drift and Image Quality Degradation

Calibration drift is a silent but serious issue. Imaging systems may continue operating while slowly producing inaccurate images.

Impact

- Poor image clarity

- Misdiagnosis risk

- Repeat scans and higher radiation exposure

Solution

- Follow OEM-recommended calibration intervals

- Perform periodic detector uniformity and alignment checks

- Validate image output after every major service

Addressing calibration drift is essential to solving medical imaging equipment maintenance challenges related to diagnostic accuracy.

3. Shortage of Skilled Biomedical Engineers

Modern imaging systems are complex, software-driven, and modality-specific. A lack of trained engineers is a growing challenge.

Why this is critical

- Delayed troubleshooting

- Improper repairs

- Dependence on multiple vendors

How to solve it

- Partner with a specialized imaging service provider

- Use certified biomedical engineers with multi-modality expertise

- Enable remote diagnostics and expert escalation

Expert support ensures faster resolution and consistent service quality.

4. High Cost of Spare Parts and Repairs

Spare parts for imaging equipment are expensive, and poor maintenance often increases replacement frequency.

Common causes

- Reactive breakdown-only servicing

- Ignoring PCB-level repair possibilities

- Using incompatible or low-quality spares

Effective solution

- Adopt component-level diagnostics

- Repair PCBs instead of replacing full assemblies

- Plan spares proactively through AMC or CAMC

This approach significantly reduces long-term maintenance costs.

5. Environmental and Power-Related Issues

Many medical imaging equipment maintenance challenges originate outside the equipment itself.

Environmental risks

- Poor ventilation

- Excessive dust

- High humidity

- Power fluctuations and grounding issues

Solution

- Ensure proper HVAC and room conditions

- Stabilize power supply with UPS and grounding

- Perform periodic environmental audits

Maintaining the right environment protects sensitive imaging electronics and extends system life.

6. Regulatory and Compliance Pressure

Imaging systems must comply with strict safety and quality regulations. Failure to meet these standards can result in penalties or operational shutdowns.

Key compliance areas

- Radiation safety

- Calibration documentation

- Preventive maintenance records

How to address it

- Maintain detailed service and calibration logs

- Perform regular safety and radiation tests

- Prepare audit-ready documentation

Proper documentation helps overcome medical imaging equipment maintenance challenges related to audits and inspections.

7. Poor Preventive Maintenance Planning

Many facilities still rely heavily on reactive maintenance, addressing problems only after failure.

Risks

- Higher downtime

- Increased emergency repair costs

- Reduced equipment lifespan

Best practice

- Create a structured preventive maintenance schedule

- Track maintenance history and trends

- Combine preventive care with fast corrective response

Preventive maintenance is the most effective way to reduce recurring maintenance challenges.

How Preventive Maintenance Solves Multiple Challenges

Preventive maintenance addresses several medical imaging equipment maintenance challenges at once:

- Detects faults early

- Maintains calibration accuracy

- Reduces emergency breakdowns

- Improves compliance readiness

- Extends equipment lifespan

A well-executed preventive strategy transforms maintenance from a cost center into a reliability driver.

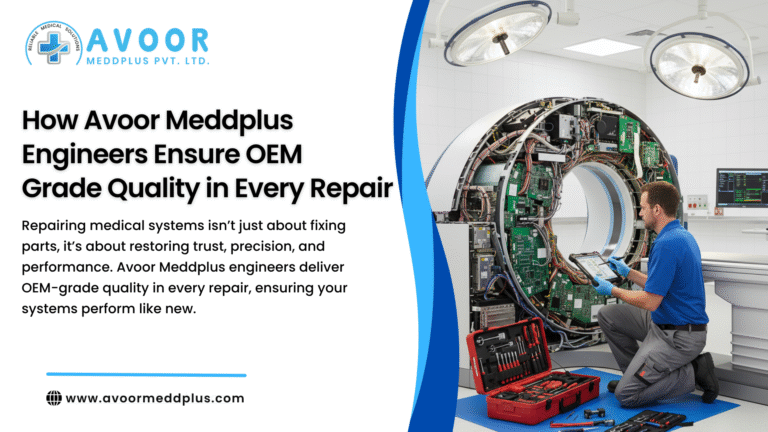

How Avoor Meddplus Helps Overcome These Challenges

Avoor Meddplus provides comprehensive imaging equipment support through:

- Certified biomedical engineers

- OEM-grade calibration and validation

- PCB-level repair expertise

- Preventive maintenance programs

- Fast response breakdown support

- Compliance-ready documentation

- Nationwide service coverage

By combining technical expertise with structured processes, Avoor Meddplus helps healthcare facilities overcome even the most complex medical imaging equipment maintenance challenges.

Conclusion

Medical imaging equipment maintenance challenges are unavoidable — but they are manageable. Unplanned downtime, calibration drift, skill shortages, high repair costs, and compliance pressures can all be controlled with the right strategy.

By prioritizing preventive maintenance, partnering with experienced service providers, and maintaining strict calibration and documentation standards, healthcare facilities can ensure reliable imaging performance and consistent diagnostic accuracy.

With expert support from Avoor Meddplus, imaging systems remain safe, compliant, and ready to deliver high-quality diagnostics every day.