Introduction

Accurate diagnosis is the foundation of effective medical treatment. From early disease detection to treatment planning and follow-up, clinicians rely heavily on diagnostic equipment to deliver precise and reliable results. However, even the most advanced imaging systems cannot maintain accuracy on their own. This is where trusted medical equipment maintenance diagnostic accuracy becomes critical.

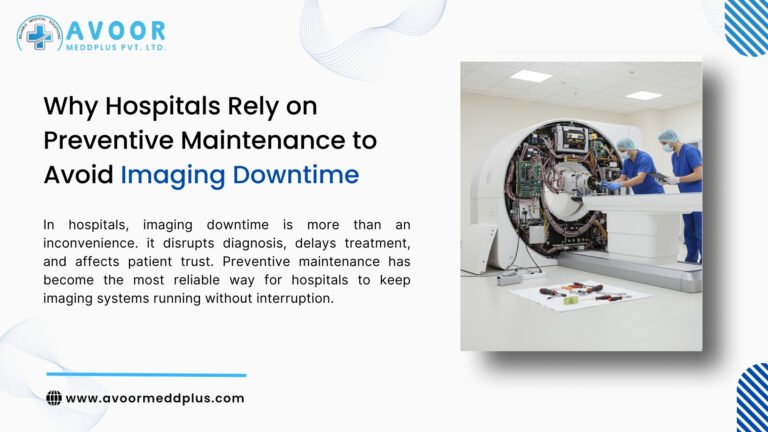

Trusted maintenance ensures that imaging systems such as CT, PET/CT, DR, C-ARM, SPECT/CT, and mammography continue to perform at OEM-specified levels. At Avoor Meddplus, preventive maintenance, expert calibration, and certified biomedical engineering support work together to protect diagnostic accuracy and clinical confidence.

This blog explains how trusted medical equipment maintenance directly improves diagnostic accuracy and why hospitals cannot afford to compromise on it.

1. Trusted Medical Equipment Maintenance Diagnostic Accuracy Starts with Precision

Diagnostic accuracy depends on precision. Imaging systems use complex combinations of detectors, power supplies, software algorithms, and mechanical alignment. Even minor deviations can distort images or measurements.

Trusted medical equipment maintenance diagnostic accuracy ensures:

- Correct detector alignment

- Stable radiation output

- Accurate exposure parameters

- Reliable software performance

When maintenance is handled by experienced professionals using OEM-grade procedures, equipment continues to produce clinically reliable images without drift or inconsistency.

2. Preventive Maintenance Prevents Diagnostic Errors

Preventive maintenance is the most effective way to protect diagnostic accuracy. Instead of reacting to breakdowns, trusted maintenance focuses on early detection of performance issues.

Common problems identified during preventive maintenance include:

- Calibration drift

- Detector non-uniformity

- Overheating components

- Power instability

- Mechanical misalignment

By addressing these issues early, preventive maintenance eliminates errors that could otherwise lead to misdiagnosis or repeat scans.

3. 5 Proven Ways Trusted Maintenance Improves Diagnostic Accuracy

1️⃣ OEM-Grade Calibration and Validation

Calibration ensures that imaging output matches real anatomical and physiological values. Trusted maintenance follows OEM-recommended calibration protocols for:

- CT slice thickness and HU accuracy

- PET/CT and SPECT/CT alignment

- DR and mammography detector uniformity

- C-ARM fluoroscopy output

OEM-grade calibration is essential for maintaining consistent diagnostic accuracy over time.

2️⃣ Consistent Image Quality Across All Scans

Inconsistent maintenance often results in fluctuating image quality. One scan may appear normal while the next shows noise or artifacts.

Trusted medical equipment maintenance diagnostic accuracy ensures:

- Uniform image clarity

- Stable contrast and resolution

- Reduced artifacts

- Reliable image reconstruction

This consistency helps radiologists interpret images with confidence.

3️⃣ Reduced Repeat Scans and Radiation Exposure

Poorly maintained equipment often requires repeat scans due to unclear or inaccurate images. This increases radiation exposure and wastes clinical time.

Trusted maintenance reduces repeat scans by:

- Maintaining calibration accuracy

- Ensuring stable detector performance

- Preventing image distortion

Lower repeat rates directly improve patient safety and workflow efficiency.

4️⃣ Compliance with Safety and Quality Standards

Diagnostic accuracy is closely tied to compliance. Regulatory bodies require imaging systems to meet strict performance and safety criteria.

Trusted maintenance supports compliance by providing:

- Regular performance testing

- Radiation output verification

- Calibration certificates

- Preventive maintenance documentation

Compliance not only protects facilities during audits but also ensures consistent diagnostic reliability.

5️⃣ Faster Clinical Decision-Making

When imaging systems are reliable, clinicians can make decisions faster. Trusted maintenance ensures equipment uptime and accuracy, enabling:

- Faster reporting

- Reduced patient waiting time

- Improved treatment planning

- Higher clinician confidence

Accurate imaging directly improves patient outcomes.

4. Role of Trusted Maintenance Across Imaging Modalities

Trusted medical equipment maintenance diagnostic accuracy applies to all imaging systems:

CT & PET/CT

- Gantry alignment

- Detector calibration

- Dose accuracy

- Fusion alignment

DR & CR

- Flat-panel calibration

- Exposure linearity

- Image uniformity

C-ARM

- Fluoroscopy brightness and contrast

- Radiation dose control

- Mechanical stability

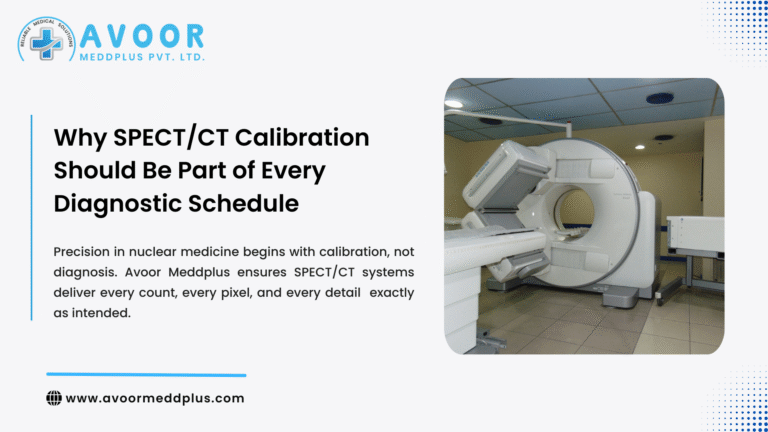

SPECT/CT & Nuclear Medicine

- Energy peaking

- COR calibration

- Uniformity correction

- Fusion accuracy

Each modality requires specialized expertise to maintain diagnostic precision.

5. Impact of Poor Maintenance on Diagnostic Accuracy

When maintenance is inconsistent or unreliable, diagnostic accuracy suffers. Common consequences include:

- False positives or negatives

- Poor lesion localization

- Inaccurate measurements

- Delayed diagnosis

- Reduced clinician trust

These risks highlight why trusted maintenance is not optional but essential for quality healthcare delivery.

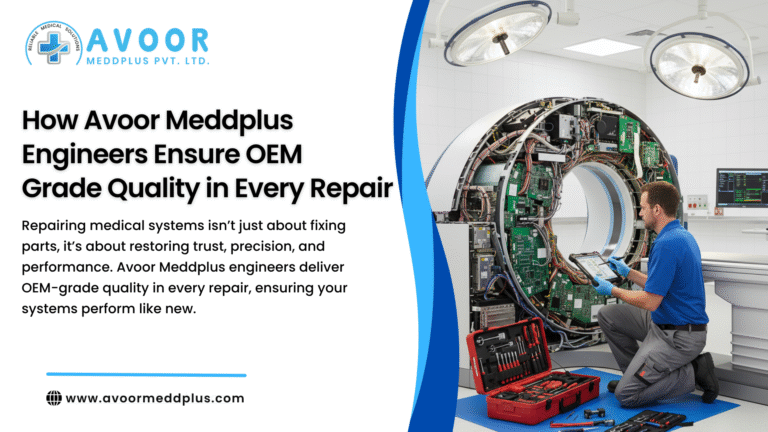

6. How Trusted Partners Strengthen Diagnostic Confidence

Hospitals benefit significantly when they work with a trusted maintenance partner. Such partners provide:

- Certified biomedical engineers

- OEM-grade tools and procedures

- Preventive maintenance programs

- Fast response during breakdowns

- Detailed documentation

Trusted partners act as an extension of hospital biomedical teams, ensuring continuous diagnostic accuracy.

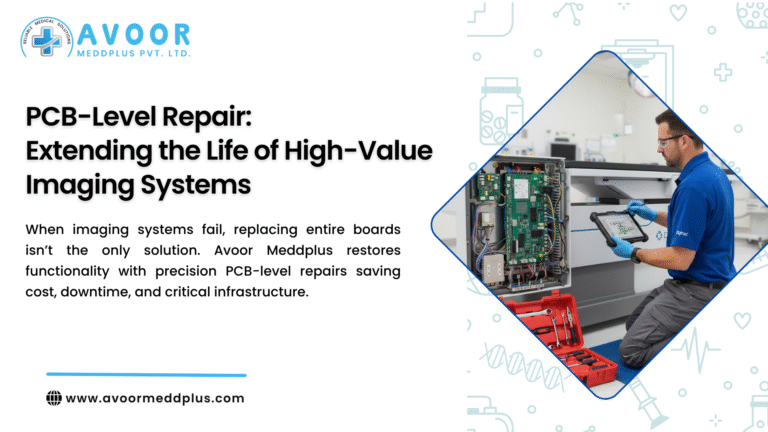

7. How Avoor Meddplus Delivers Trusted Medical Equipment Maintenance

Avoor Meddplus supports hospitals and diagnostic centers with:

- Preventive maintenance for all imaging modalities

- OEM-grade calibration and validation

- PCB-level repair expertise

- Fast response technical support

- Compliance-ready documentation

- Nationwide service coverage

Through structured processes and expert engineering, Avoor Meddplus ensures trusted medical equipment maintenance diagnostic accuracy across every system.

Conclusion

Diagnostic accuracy depends not only on advanced technology but also on how well that technology is maintained. Trusted medical equipment maintenance diagnostic accuracy ensures consistent image quality, regulatory compliance, reduced repeat scans, and confident clinical decision-making.

By investing in preventive maintenance and partnering with experienced service providers like Avoor Meddplus, hospitals protect patient safety, improve outcomes, and maintain the highest diagnostic standards.