Introduction

In healthcare, trust is not optional—it is essential. Hospitals and diagnostic centers rely on medical equipment every day to deliver accurate diagnoses, guide treatments, and ensure patient safety. When equipment fails, the quality of repair and the level of compliance followed during service directly determine whether that trust is strengthened or lost.

This is why building trust in medical equipment repair through quality and compliance has become a critical priority for healthcare providers. Repair is no longer just about restoring functionality; it is about ensuring safety, accuracy, regulatory adherence, and long-term reliability. At Avoor Meddplus, trust is built through disciplined service processes, OEM-grade quality standards, and strict compliance practices.

1. Why Trust Matters in Medical Equipment Repair

Medical equipment directly impacts patient outcomes. A poorly repaired imaging system can lead to:

- Inaccurate diagnostic results

- Increased radiation exposure

- Repeat scans

- Clinical delays

- Safety risks for patients and staff

Because of these risks, hospitals cannot afford uncertainty in repair quality. Trust is earned when service providers demonstrate consistency, transparency, and compliance across every repair activity.

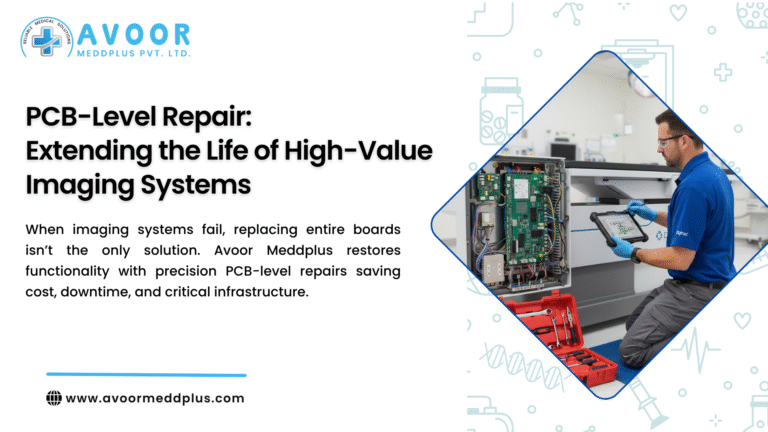

2. Quality as the Foundation of Trust

Quality repair goes beyond replacing faulty parts. It involves restoring equipment performance to manufacturer-defined standards.

High-quality medical equipment repair includes:

- Accurate fault diagnosis

- OEM-grade repair procedures

- Component-level (PCB) repair when appropriate

- Post-repair calibration and validation

- Performance testing under clinical conditions

When quality is consistent, hospitals gain confidence that repaired equipment will perform reliably over time.

3. Compliance Ensures Safety and Accountability

Compliance is the second pillar of trust. Medical equipment repair must follow regulatory and safety guidelines established by authorities and accreditation bodies.

Key compliance areas include:

- Radiation safety testing

- Electrical safety and grounding checks

- Calibration documentation

- Preventive maintenance records

- Traceable service history

Compliance protects hospitals during audits and ensures that repaired equipment meets legal and safety requirements.

4. 5 Key Ways Quality and Compliance Build Trust in Medical Equipment Repair

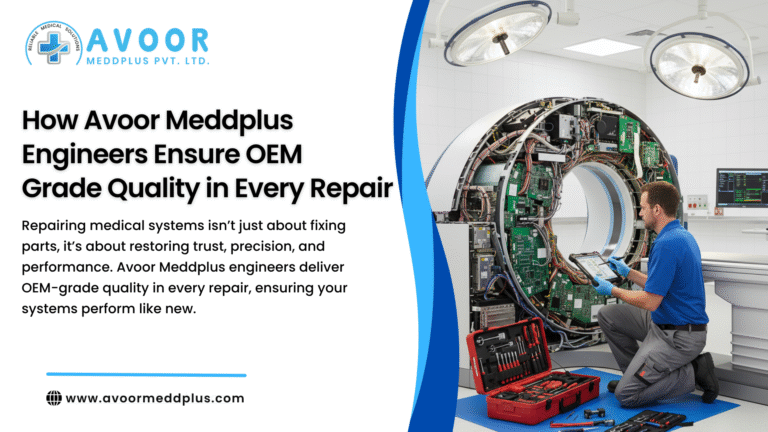

1️⃣ OEM-Grade Repair Standards

Trust is built when repairs follow OEM-recommended methods rather than shortcuts. OEM-grade standards ensure:

- Correct tolerances

- Accurate performance restoration

- Long-term stability

Hospitals trust service partners who never compromise on repair quality.

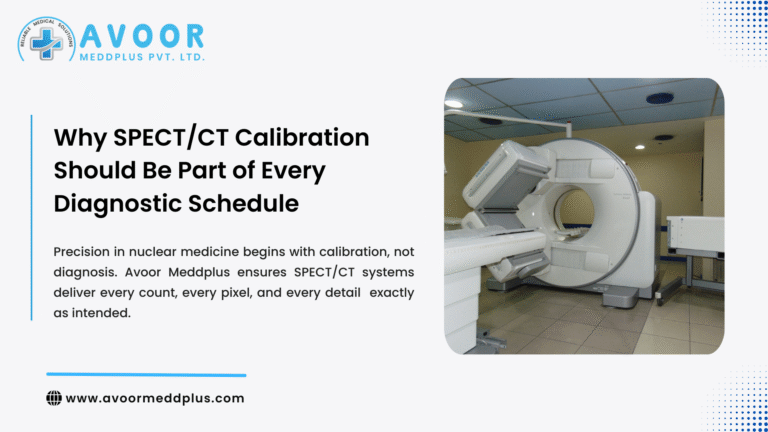

2️⃣ Post-Repair Calibration and Validation

A repair is incomplete without calibration. Quality-focused service includes:

- Radiation output verification

- Detector alignment

- Image quality validation

- Software and DICOM checks

This ensures that repaired equipment produces accurate and reliable diagnostic results.

3️⃣ Certified and Skilled Biomedical Engineers

Experienced and certified biomedical engineers are essential for trustworthy repairs. Their expertise allows them to:

- Identify root causes accurately

- Perform safe repairs

- Follow compliance protocols

- Maintain proper documentation

Skilled engineers reduce repeat failures and improve confidence in service outcomes.

4️⃣ Transparent Documentation and Reporting

Trust grows when hospitals receive clear and complete service documentation. Quality repair includes:

- Detailed fault analysis reports

- Parts replaced or repaired

- Calibration certificates

- Safety test results

Transparent reporting creates accountability and supports regulatory compliance.

5️⃣ Consistent Performance After Repair

The true test of trust is how equipment performs after repair. High-quality, compliant repairs result in:

- Fewer repeat issues

- Stable image quality

- Predictable uptime

- Reduced emergency calls

Consistency reinforces long-term trust between hospitals and service providers.

5. Risks of Poor-Quality or Non-Compliant Repairs

When quality and compliance are ignored, hospitals face serious risks:

- Recurring breakdowns

- Diagnostic inaccuracies

- Safety incidents

- Audit failures

- Higher long-term maintenance costs

- Loss of clinician confidence

These consequences highlight why hospitals increasingly evaluate service partners based on repair quality and compliance discipline.

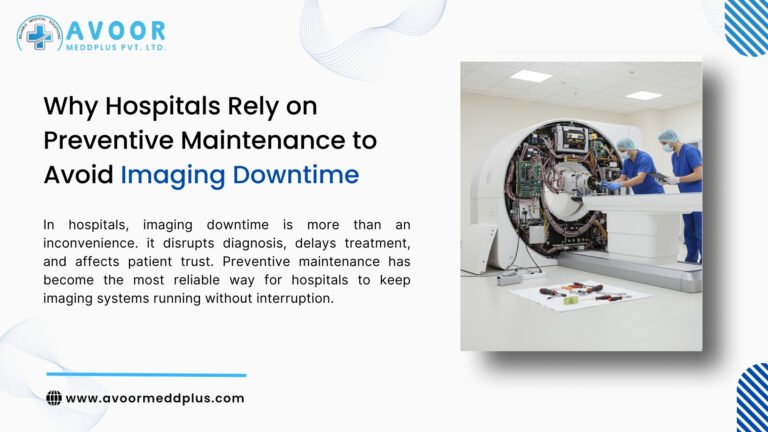

6. Role of Preventive Maintenance in Trust Building

Repair quality is closely linked to preventive maintenance. A service partner committed to trust does not wait for failures.

Preventive maintenance supports trust by:

- Detecting early signs of failure

- Maintaining calibration accuracy

- Reducing emergency breakdowns

- Ensuring continuous compliance

Preventive care demonstrates a proactive, quality-driven approach to equipment management.

7. How Avoor Meddplus Builds Trust Through Quality and Compliance

Avoor Meddplus builds long-term trust with hospitals and diagnostic centers through:

- OEM-grade repair and calibration

- Certified biomedical engineers

- PCB-level repair expertise

- Structured preventive maintenance programs

- Radiation and electrical safety testing

- Compliance-ready documentation

- Nationwide service coverage

Every repair is treated as a responsibility toward patient safety and diagnostic accuracy, not just a technical task.

8. Trust Translates into Better Clinical Confidence

When clinicians trust repaired equipment, they:

- Rely on imaging results without hesitation

- Reduce repeat scans

- Make faster, confident decisions

- Deliver better patient care

Trust in repair quality directly improves clinical workflow and outcomes.

Conclusion

In healthcare, trust is earned through consistency, transparency, and responsibility. Building trust in medical equipment repair through quality and compliance ensures that repaired systems are safe, accurate, and reliable long after service is completed.

Hospitals that partner with quality-driven, compliance-focused service providers reduce risk, improve uptime, and protect patient safety. Through disciplined engineering practices and strict adherence to standards, Avoor Meddplus continues to strengthen trust in medical equipment repair—one compliant, high-quality service at a time.