Introduction

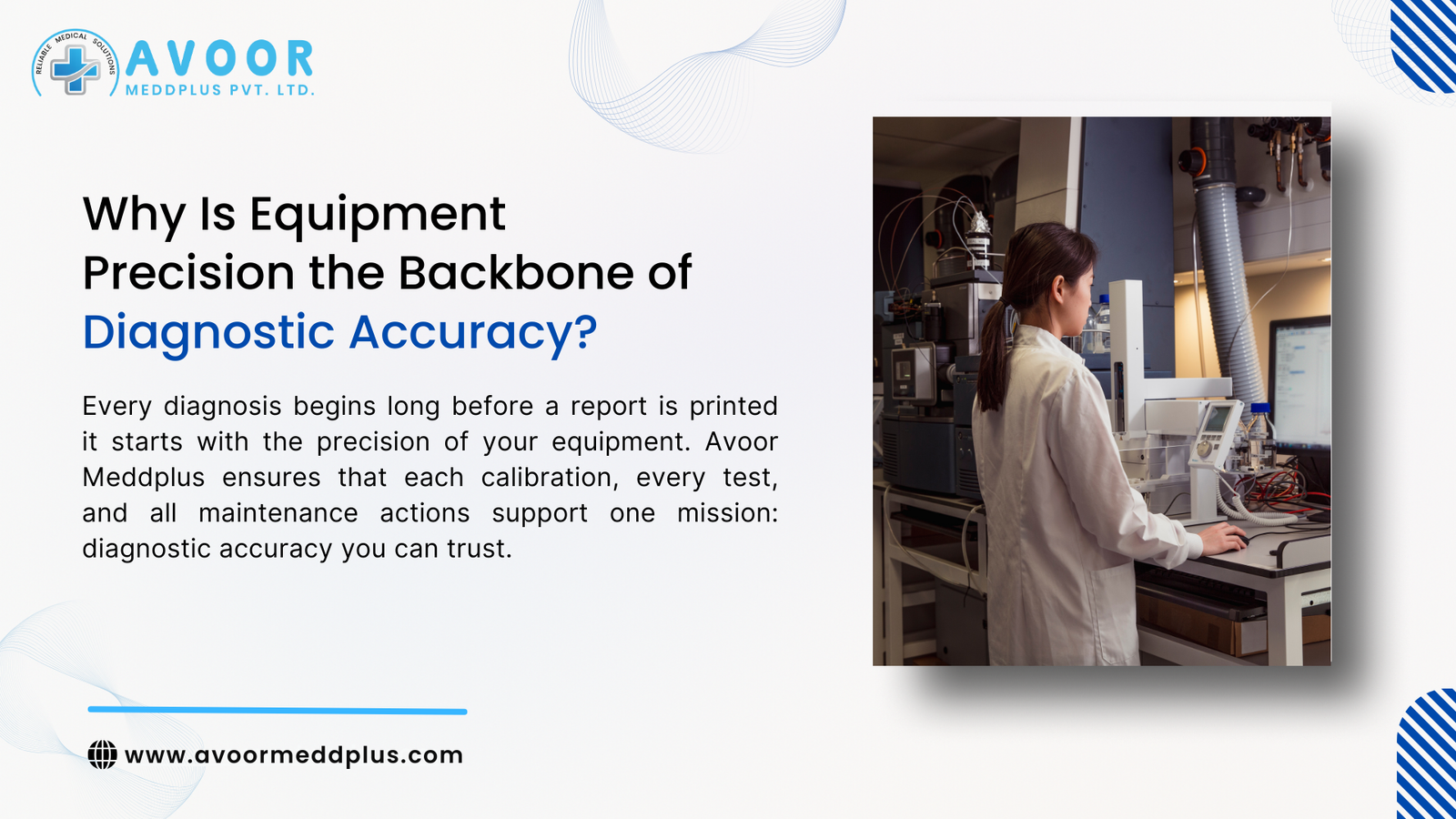

The foundation of modern diagnostic imaging lies in precision. When imaging equipment performs flawlessly, doctors receive accurate, reliable scans that support confident clinical decisions. When precision falters, diagnostic accuracy collapses leading to repeat scans, incorrect reporting, delayed treatment, and increased patient risk.

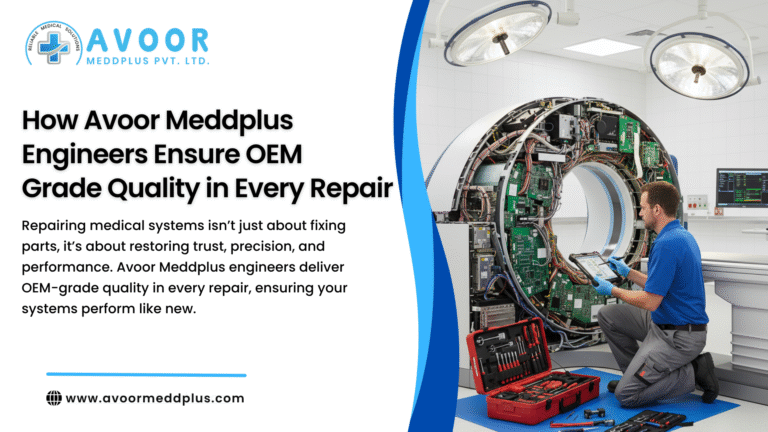

This is why equipment precision diagnostic accuracy has become one of the most essential pillars of today’s medical imaging standards. At Avoor Meddplus, we ensure that every CT, PET/CT, DR, C-ARM, and nuclear medicine system maintains OEM-grade accuracy through structured calibration, preventive maintenance, and expert engineering support.

In this article, we explore 5 expert reasons why equipment precision directly influences diagnostic accuracy and why it must never be compromised.

1. Equipment Precision Diagnostic Accuracy – Why It’s the Core of Imaging Performance

Precision is more than a technical term — it directly affects patient care. Imaging systems rely on accurate power delivery, detector performance, alignment, calibration, and radiation output to create medically actionable images.

When equipment precision drifts even slightly, the imaging output becomes inconsistent, unclear, or misleading. Biomedical teams and radiologists often face challenges such as:

- Image blurring or artifacts

- Incorrect anatomical measurements

- Misalignment in fused images (SPECT/CT, PET/CT)

- Inconsistent radiation exposure

- Errors in SUV values (nuclear medicine)

Maintaining equipment precision is therefore the first line of defense in ensuring diagnostic reliability, safety, and compliance.

2. Precision Directly Impacts Diagnostic Accuracy

Accuracy in diagnosis depends on the clarity and reliability of the images captured. Even a minor calibration drift or detector misalignment can lead to:

- False positives

- False negatives

- Poor localization of lesions

- Misinterpretation of disease severity

- Incorrect surgical planning

For modalities like CT and PET/CT, even small deviations in gantry alignment or detector performance can significantly distort imaging data.

Avoor Meddplus ensures precision through:

- Energy calibration

- Detector uniformity testing

- Gantry alignment

- Tube output verification

- DICOM accuracy checks

This guarantees that the diagnostic output is consistent and clinically reliable.

3. 5 Expert Reasons Equipment Precision Matters for Every Facility

1️⃣ Prevents Misdiagnosis and Incorrect Reporting

Reliable equipment precision ensures radiologists interpret images confidently without repeated scans or uncertainty. This directly impacts patient outcomes and reduces medical risk.

2️⃣ Reduces Repeat Scans and Radiation Exposure

Imprecise equipment often forces repeat imaging, doubling patient exposure and wasting clinical time. Maintaining precision ensures first-scan accuracy.

3️⃣ Ensures Compliance with AERB/NABH Standards

AERB guidelines mandate strict calibration and quality control for imaging systems. Precision maintenance ensures that your facility remains audit-ready with flawless documentation.

👉 Reference: AERB Medical Equipment Guidelines

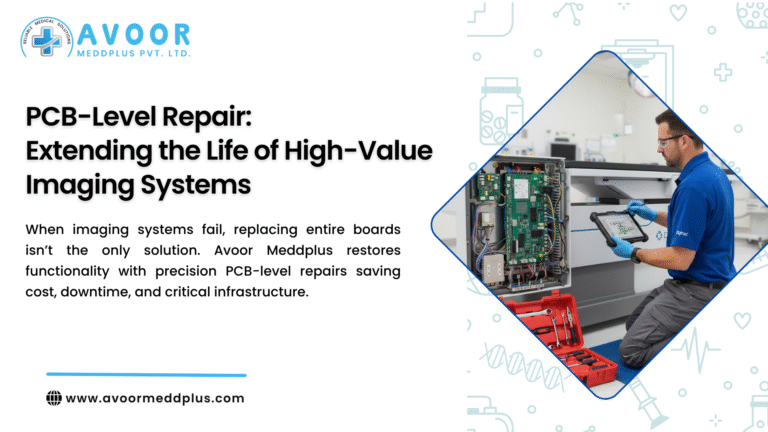

4️⃣ Improves Equipment Life and Performance Stability

Precision testing identifies early component drift, overheating, or alignment issues before they turn into costly breakdowns. This extends equipment lifespan and reduces repair costs.

5️⃣ Supports Better Surgical and Clinical Decisions

For C-ARM, Mammography, and Cathlab imaging, precision directly affects procedural outcomes. Clearer images mean safer procedures and faster clinical decisions.

4. How Avoor Meddplus Ensures Precision Across All Modalities

Avoor Meddplus engineers follow strict OEM-based protocols to maintain diagnostic accuracy across systems:

✔ CT & PET/CT

- Detector and gantry calibration

- Power and cooling performance checks

- Slice thickness verification

- DICOM and reconstruction alignment

✔ DR & CR

- Flat-panel calibration

- Exposure linearity testing

- Detector uniformity

- Image clarity checks

✔ C-ARM

- Fluoroscopy brightness and contrast alignment

- KV/mA output validation

- Real-time radiation safety testing

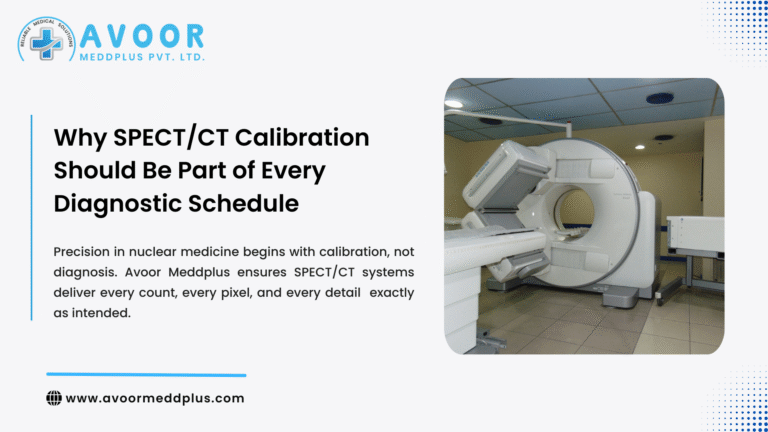

✔ SPECT/CT & Nuclear Medicine

- Energy peaking

- COR (center-of-rotation) calibration

- Uniformity correction

- Fusion alignment verification

Through structured calibration and precision testing, Avoor Meddplus ensures every imaging system performs exactly as the manufacturer intended.

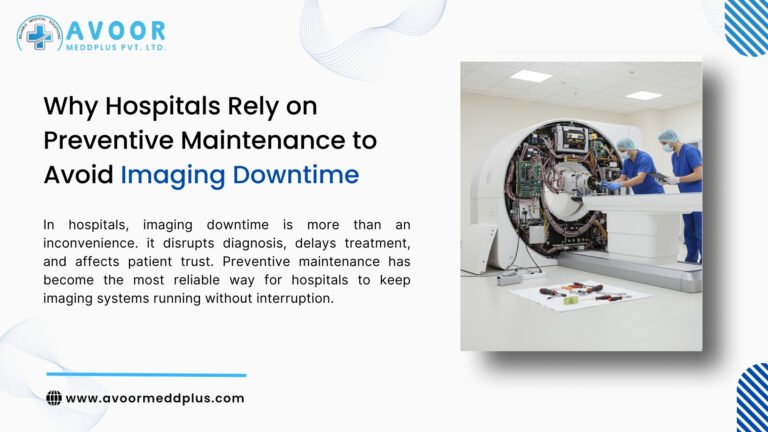

5. Preventive Maintenance – The Real Backbone of Precision

Precision is not a one-time achievement. Imaging systems require periodic preventive maintenance to preserve calibration, performance stability, and radiation safety.

Avoor Meddplus provides:

- Quarterly preventive maintenance

- OEM-grade calibration

- Detector testing

- Power supply assessment

- Alignment verification

- Radiation quality checks

This proactive care protects equipment precision, enhancing diagnostic accuracy and minimizing downtime.

6. The Hidden Cost of Poor Precision

Facilities often underestimate how much imprecision costs. Poor equipment precision contributes to:

- Increased patient complaints

- Repeated scans (wasting electricity, manpower, and radiation dose)

- Extended reporting time

- Low radiologist confidence

- Equipment strain due to incorrect operation

- Higher long-term maintenance expenses

The financial impact of imprecise systems can exceed 10–20X the cost of proper preventive calibration.

Why Avoor Meddplus Is the Trusted Partner for Precision

- Multi-modality expertise

- OEM-trained service engineers

- PCB-level diagnostic capability

- Quick fast-response service

- Accurate calibration tools

- Full AERB-ready documentation

- 98% uptime record across clients

Avoor Meddplus ensures equipment precision stays intact and diagnostic accuracy stays uncompromised.

Conclusion

Precise equipment leads to precise diagnosis. As imaging becomes more advanced and patient expectations grow, maintaining equipment precision diagnostic accuracy is no longer an option, it is mandatory.

With OEM-grade calibration, structured preventive maintenance, and expert engineering support, Avoor Meddplus keeps every imaging system reliable, accurate, and audit-ready.