Introduction

Hot lab equipment calibration and maintenance play a vital role in nuclear medicine safety , where precision defines safety and accuracy. Every dose calibrator, survey meter, and contamination monitor plays a vital role in ensuring radiation safety and accurate radiopharmaceutical measurement.

At Avoor Meddplus, we provide expert calibration and preventive maintenance to help nuclear medicine departments comply with AERB safety standards and achieve consistent diagnostic results. Our focus is simple safety, accuracy, and compliance first.

1. The Importance of Calibration in Hot Lab Equipment

Hot lab instruments, including dose calibrators, survey meters, and contamination detectors, must measure radiation levels with absolute precision. A single calibration error can lead to incorrect dosage, overexposure, or diagnostic inaccuracy.

Regular calibration ensures:

- Reliable and repeatable readings

- Protection against radiation hazards

- Compliance with AERB and IAEA guidelines

- Extended equipment life and reduced maintenance costs

Proper calibration is not optional — it’s the foundation of patient safety in nuclear medicine.

2. 5 Expert Reasons Why Regular Maintenance Is Essential

1️⃣ Accuracy Assurance: Routine testing prevents drift and ensures measurement stability.

2️⃣ Regulatory Compliance: Adheres to strict AERB standards for dose calibrator accuracy and radiation protection.

3️⃣ Operational Efficiency: Prevents unplanned downtime and costly replacements.

4️⃣ Staff and Patient Safety: Maintains shielding integrity and contamination-free operation.

5️⃣ Performance Longevity: Regular service enhances reliability and extends equipment lifespan.

These five factors make professional maintenance an investment in safety and sustainability.

3. Calibration Process Followed by Avoor Meddplus

Our AERB-compliant calibration protocol includes:

- Energy response and linearity testing of dose calibrators

- Background and contamination level verification

- Radiation counter validation

- Survey meter and detector recalibration

- Quality control documentation for certification

Each procedure follows OEM and IAEA radiation standards, ensuring every hot lab system delivers precise, traceable results.

👉 Reference: AERB Official Site – Radiation Safety Guidelines

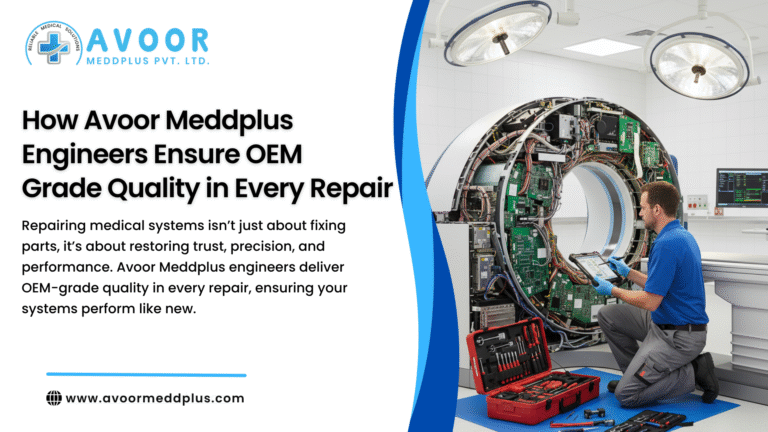

4. Common Hot Lab Equipment Issues Detected During Service

- Detector instability or misalignment

- Leakage or shielding degradation

- Power fluctuations affecting readings

- Software or display calibration errors

- Radiation drift due to environmental conditions

Avoor Meddplus engineers identify these issues early and restore systems to OEM-level accuracy, minimizing downtime and compliance risks.

5. Preventive Maintenance for Continuous Compliance

Our maintenance plans include scheduled inspections, radiation safety validation, and calibration traceability. This proactive approach ensures:

- Compliance with NABH and AERB inspection requirements

- Detailed documentation for audits and licensing renewals

- Consistent radiation monitoring and contamination control

Preventive service is the most cost-effective way to maintain high accuracy and reduce emergency service calls.

6. Why Choose Avoor Meddplus for Hot Lab Calibration

- Certified nuclear medicine service engineers

- OEM-standard calibration tools and reference sources

- Nationwide on-site service

- Fast turnaround with detailed QA reports

- Proven record of improving uptime and compliance across India

Our team ensures every calibration not only meets but exceeds regulatory expectations making your hot lab both safe and audit-ready.

Conclusion

Precision in nuclear medicine starts in the hot lab. Through expert calibration, radiation testing, and preventive maintenance, Avoor Meddplus guarantees equipment reliability, compliance, and accuracy. Regular service is not just a technical need it’s a commitment to safety, confidence, and diagnostic excellence.

By partnering with Avoor Meddplus, healthcare centers gain peace of mind knowing their hot lab equipment performs at peak precision every day, every scan.