Introduction

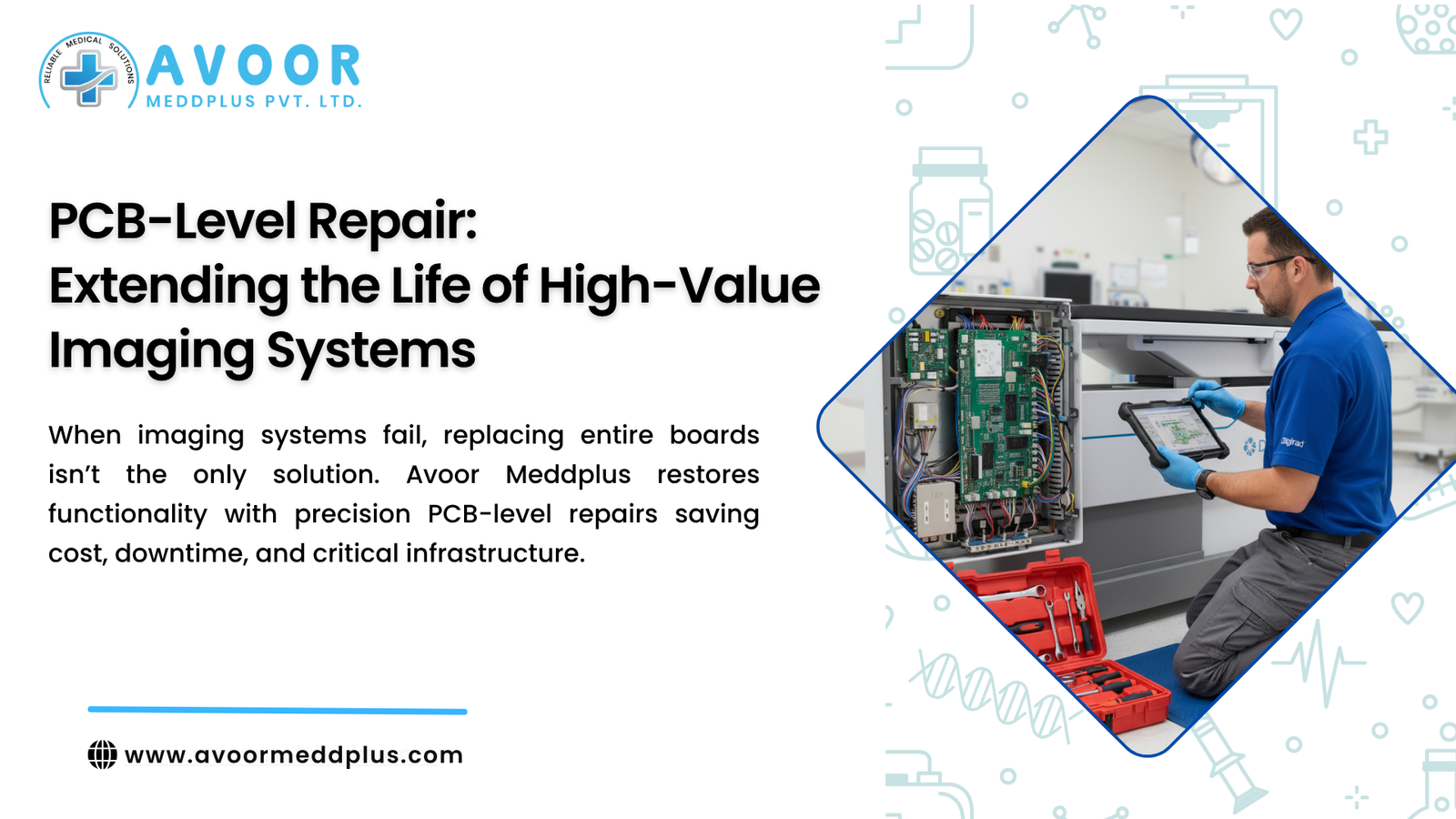

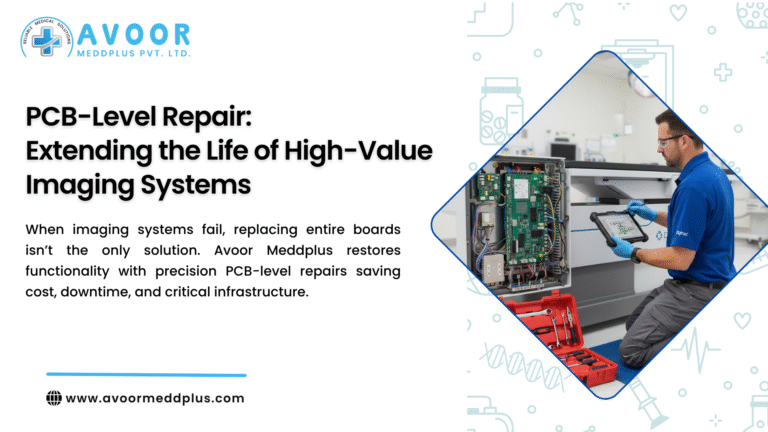

In advanced diagnostic imaging, reliability and uptime are critical. Systems like CT, MRI, DR, and PET/CT scanners rely on complex electronic control boards that manage image acquisition, signal processing, and system safety. When these boards fail, replacing them can be expensive often accounting for 30–40% of the system’s total cost. That’s why PCB-level repair has become a strategic, cost-effective solution for hospitals and imaging centers seeking to extend the life of high-value equipment without compromising performance or safety.

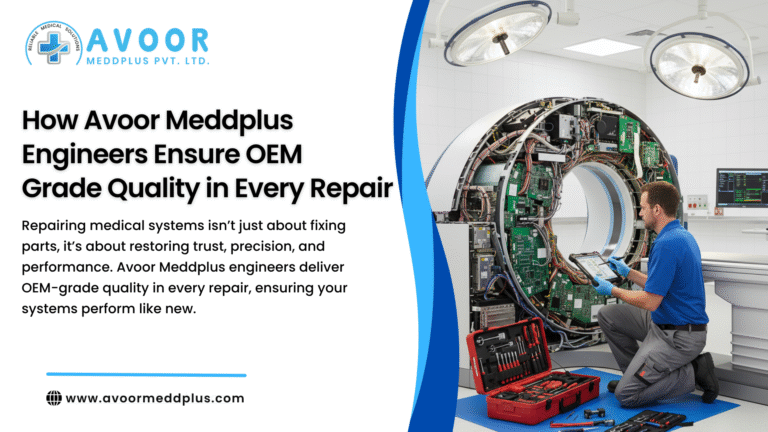

At Avoor Meddplus, we specialize in board-level diagnostics and repair for medical imaging systems, offering OEM-quality precision and long-term reliability.

1. Understanding PCB-Level Repair in Imaging Systems

Printed Circuit Boards (PCBs) are the central nervous system of imaging equipment. They control everything from detector output to image reconstruction and power management. A single malfunctioning capacitor or IC can disrupt imaging workflows or cause total system failure.

Unlike simple module swaps, PCB-level repair focuses on restoring individual electronic components such as microchips, resistors, or connectors instead of replacing the entire board. This approach ensures cost savings, minimal downtime, and sustainable operation.

2. 5 Expert Ways PCB-Level Repair Extends Equipment Life

1️⃣ Early Fault Detection

Avoor Meddplus engineers use advanced diagnostic tools like oscilloscopes and in-circuit testers to identify component-level faults before total failure occurs.

2️⃣ OEM-Grade Component Replacement

Defective capacitors, ICs, and diodes are replaced with OEM-spec components, restoring original functionality and signal integrity.

3️⃣ Precision Re-Soldering and Micro Repair

Our trained technicians perform micro-soldering and PCB trace restoration under magnification to achieve factory-level accuracy.

4️⃣ Bench Testing and Simulation

Every repaired board undergoes bench simulation in test environments that replicate real imaging conditions, ensuring stability and safety.

5️⃣ Firmware Reinstallation and Calibration

Once the PCB passes diagnostics, firmware and calibration parameters are restored to OEM settings for consistent image quality and system responsiveness.

These five practices guarantee that the repaired board performs identically to a new one at a fraction of the replacement cost.

3. Common PCB Faults Found in Imaging Equipment

- Power supply unit failures due to surge or heat damage

- Shorted ICs or blown fuses in control boards

- Communication faults between CPU and detector modules

- Corrosion from environmental humidity

- Software lockups caused by voltage fluctuation or firmware errors

Through preventive analysis and component-level repair, Avoor Meddplus eliminates these issues before they affect diagnostic operations.

4. Why Choose PCB-Level Repair Over Board Replacement

Replacing PCBs in imaging systems can cost lakhs of rupees and often involves long procurement delays. In contrast, Avoor Meddplus PCB repair offers:

- Cost Savings: Repairs cost 50–70% less than full replacements.

- Quick Turnaround: On-site and lab-level repair options reduce downtime.

- Environmental Responsibility: Extends product life, reducing electronic waste.

- OEM-Level Standards: Repairs performed using certified tools and protocols.

Hospitals and diagnostic centers across India trust Avoor Meddplus to restore and sustain their imaging infrastructure efficiently.

5. Ensuring Quality and Reliability After Repair

Every repaired board undergoes a multi-stage quality process:

- Electrical continuity testing

- Load testing under operating conditions

- Signal verification with OEM calibration tools

- Final installation and performance validation

👉 Reference: DICOM Official Standards for Medical Imaging

This ensures complete system reliability and compliance with AERB and NABH safety standards.

6. Long-Term Benefits of PCB-Level Repair

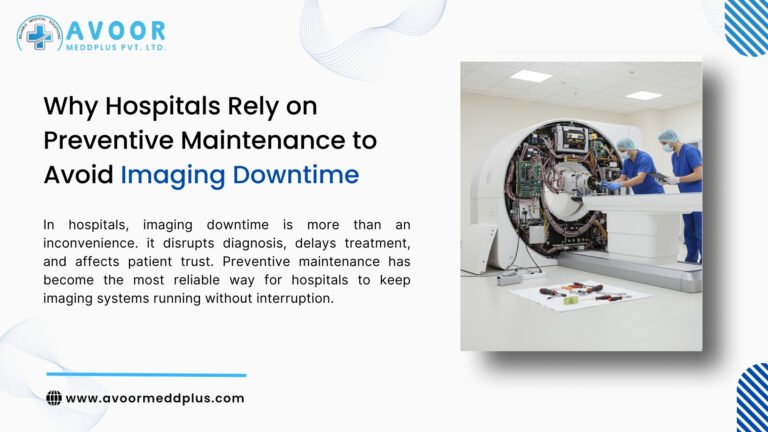

- Minimized Downtime: Quick turnaround reduces patient service disruption.

- Predictable Maintenance Costs: Eliminates unexpected replacement expenses.

- Extended Equipment Lifecycle: Systems remain operational for years beyond warranty.

- Sustainable Service Model: Reduces dependence on OEM spares while maintaining full functionality.

With routine maintenance and timely PCB-level servicing, imaging departments can maintain near-constant uptime and diagnostic accuracy.

7. Why Choose Avoor Meddplus for PCB-Level Repair

- Certified biomedical and electronic engineers with OEM-level expertise

- Advanced component testing and rework infrastructure

- Comprehensive calibration and quality verification

- Nationwide service coverage with rapid response

- Proven record of restoring high-value imaging systems with precision

Avoor Meddplus blends engineering excellence with cost efficiency, ensuring that every PCB repair adds measurable value to your diagnostic investment.

Conclusion

In today’s healthcare ecosystem, equipment uptime and performance are non-negotiable. PCB-level repair bridges the gap between reliability and affordability allowing hospitals to extend the life of expensive imaging systems without sacrificing diagnostic accuracy.

With Avoor Meddplus, every repair is executed to OEM standards, tested for precision, and validated for safety keeping your imaging systems running longer, faster, and more efficiently.