Introduction

Imaging centers depend on consistent performance, accuracy, and uptime across critical equipment such as CT, PET/CT, DR, CR, C-ARM, SPECT/CT, and Mammography systems. These machines must deliver reliable results every single day to support doctors, radiologists, and surgeons. This is why preventive maintenance imaging reliability has become a crucial part of every facility’s operational strategy.

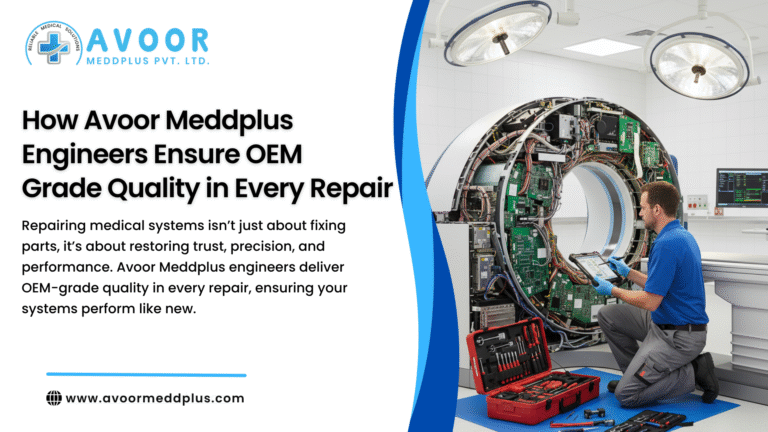

Preventive maintenance is not simply an optional service. it is a powerful tool that strengthens system performance, reduces downtime, enhances diagnostic accuracy, and extends equipment lifespan. At Avoor Meddplus, we ensure that every imaging system runs with OEM-grade reliability through structured, proactive maintenance programs.

1. Preventive Maintenance Imaging Reliability Why It Is Essential

The entire concept of imaging reliability is built on precision. Imaging devices rely on:

- Aligned detectors

- Stable power supplies

- Calibrated tubes

- Balanced cooling systems

- Accurate DICOM communication

- Clean, uniform detectors

When any one of these elements is compromised, imaging consistency degrades. This is why preventive maintenance imaging reliability is not just beneficial but essential for every diagnostic facility. It ensures each component works within OEM-defined tolerances, preventing errors, variation, and image drift.

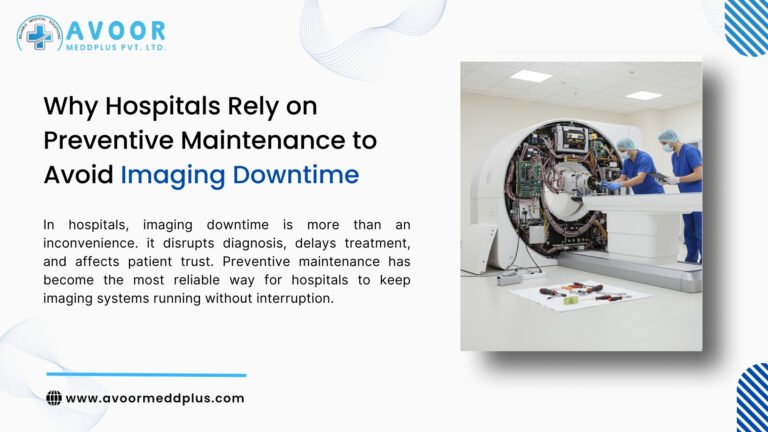

2. Preventive Maintenance Reduces Unplanned Downtime

Unplanned downtime is one of the biggest threats to diagnostic operations. It results in delayed patient scanning, disrupted reporting schedules, and serious workflow challenges for doctors and technicians.

Preventive maintenance significantly reduces downtime by:

- Identifying failing components before they break

- Checking detector performance proactively

- Catching power and cooling abnormalities

- Ensuring consumables and parts are replaced at the right time

- Performing alignment and calibration before issues occur

A facility that follows structured preventive maintenance experiences up to 70% fewer breakdowns.

3. 5 Expert Ways Preventive Maintenance Boosts Imaging Reliability

1️⃣ Ensures Consistent Image Quality

Image drift is common in systems that run long hours without maintenance. Issues like detector non-uniformity, noise, and misalignment may arise. Preventive maintenance keeps output stable and accurate, maintaining clear, uniform, and diagnostically valuable images.

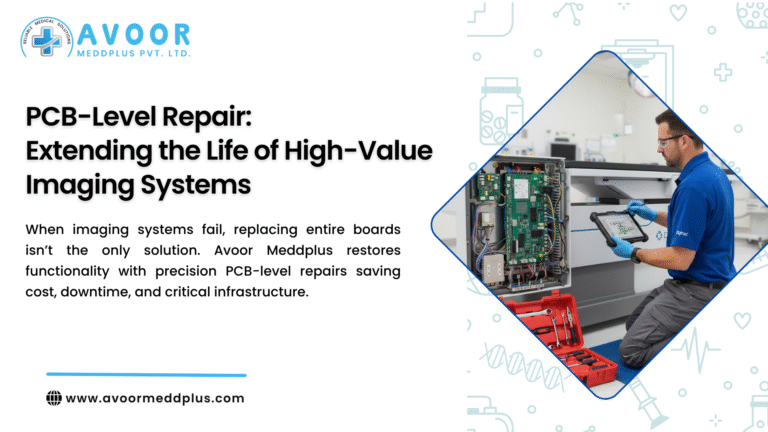

2️⃣ Extends Equipment Lifespan

Imaging systems are expensive long-term assets. Preventive care reduces the strain on core components, extends tube life, and prevents PCB-level issues. Facilities that invest in preventive maintenance often gain several extra years of reliable performance from their systems.

3️⃣ Reduces Costly Repairs and Emergency Breakdowns

Emergency repairs are costly and unpredictable. Preventive maintenance helps detect:

- Loose connectors

- Overheating boards

- Low cooling efficiency

- Voltage fluctuations

- Calibration drift

Addressing these early prevents major failures and sudden expenses.

4️⃣ Helps Maintain AERB/NABH Compliance

Imaging systems must meet strict regulatory guidelines for radiation safety and equipment upkeep.

Preventive maintenance ensures that hospitals stay audit-ready with complete test reports, calibration sheets, and service documentation.

5️⃣ Improves Clinical Workflow Efficiency

When imaging systems run reliably, everything works better:

- Fewer patient reschedules

- Faster reporting

- Reduced radiation exposure

- Higher radiologist confidence

- Smooth OT workflows (for C-ARM and Cathlab)

Better equipment reliability means better patient care.

4. What Preventive Maintenance Includes in Modern Imaging Systems

✔ CT & PET/CT Systems

- Gantry and detector calibration

- Tube load testing

- Cooling system performance check

- Slice thickness verification

- DICOM calibration

✔ DR & CR Systems

- Flat-panel detector calibration

- Uniformity & linearity testing

- Tube accuracy verification

- Detector pixel health review

✔ C-ARM Systems

- Fluoroscopy power output validation

- KV/mA accuracy

- II tube or flat-panel evaluation

- Mechanical & grounding checks

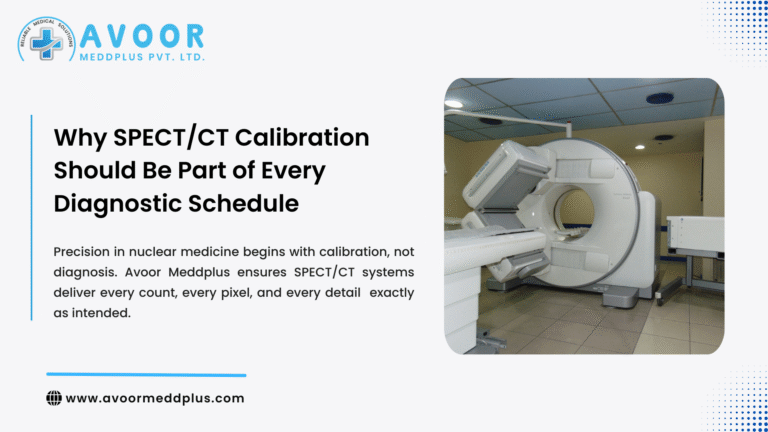

✔ SPECT/CT & Nuclear Medicine

- Energy peaking

- Uniformity correction

- COR calibration

- Fusion verification

✔ Mammography Systems

- Compression accuracy

- Dose consistency

- Image clarity and contrast testing

These steps ensure reliable performance across all imaging systems.

5. The Hidden Cost of Skipping Preventive Maintenance

Many facilities delay preventive service because the machine “seems fine.” However, skipping maintenance often leads to:

- Sudden breakdowns

- Repeat scans

- Poor image output

- Extended analyzer rejections

- High repair costs

- Regulatory non-compliance

- Lost revenue

The financial impact of reactive-only servicing can exceed 10–20× the cost of proper preventive care.

6. How Avoor Meddplus Strengthens Imaging Reliability

Avoor Meddplus supports imaging facilities with:

- OEM-trained service engineers

- Precision calibration tools

- PCB-level repair capability

- Fast response support

- Audit-ready service documentation

- Nationwide engineer network

- Structured preventive maintenance schedules

- Low-cost AMC/CAMC/per-call options

Our preventive maintenance programs help hospitals achieve 98% uptime and consistent imaging reliability.

Conclusion

The role of preventive maintenance has never been more important. As imaging technology becomes advanced and more sensitive, facilities cannot afford breakdowns, image errors, or inconsistent performance.

The preventive maintenance imaging reliability approach ensures diagnostic accuracy, reduces downtime, extends equipment life, and supports smooth clinical operations. With expert service, calibration, and predictive maintenance, Avoor Meddplus keeps every imaging system performing at OEM-grade standards.