Introduction

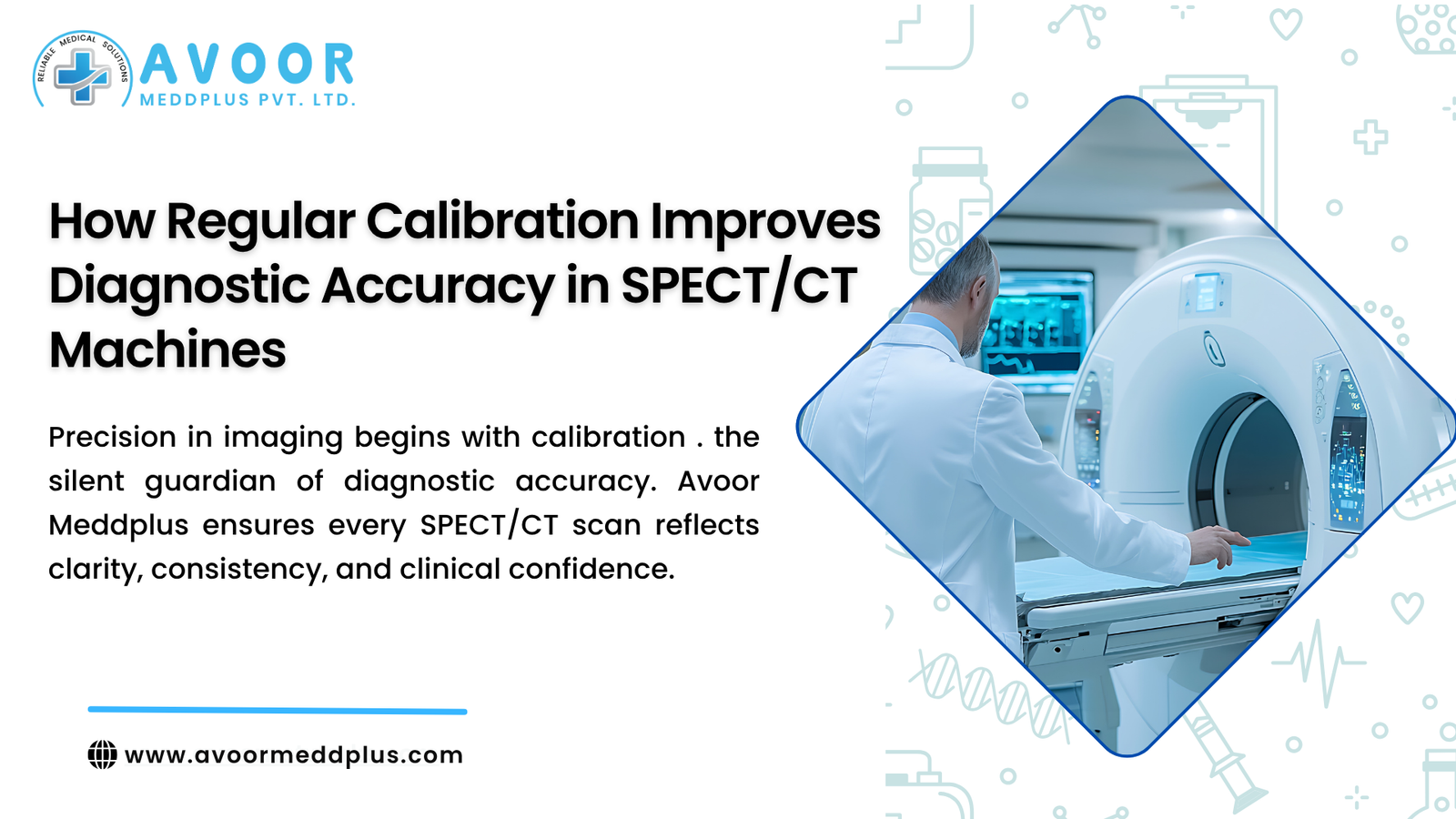

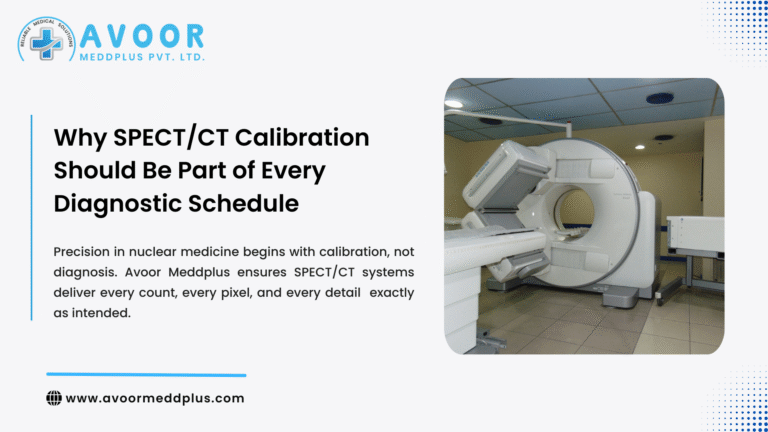

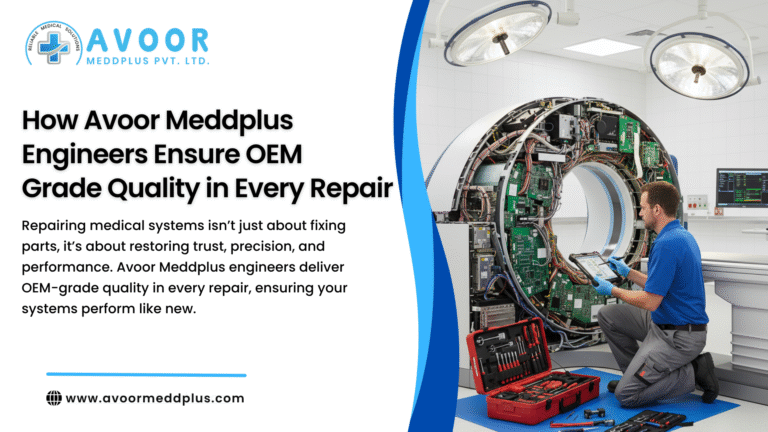

SPECT/CT calibration and preventive maintenance play a crucial role in maintaining the accuracy, safety, and reliability of nuclear imaging systems. Regular calibration ensures that both the SPECT and CT modules produce precise, aligned images for confident diagnosis. At Avoor Meddplus, we specialize in maintaining OEM-grade precision through comprehensive calibration programs and proactive maintenance schedules that reduce downtime and enhance diagnostic accuracy.

1. Why Calibration Matters in SPECT/CT Systems

SPECT/CT combines molecular and anatomical imaging to deliver critical insights in cardiology, oncology, and neurology. Calibration ensures these two imaging modalities are perfectly aligned, minimizing distortion, artifacts, and inaccurate measurements. Without proper calibration, even minor deviations can lead to misinterpretation and delayed treatment decisions.

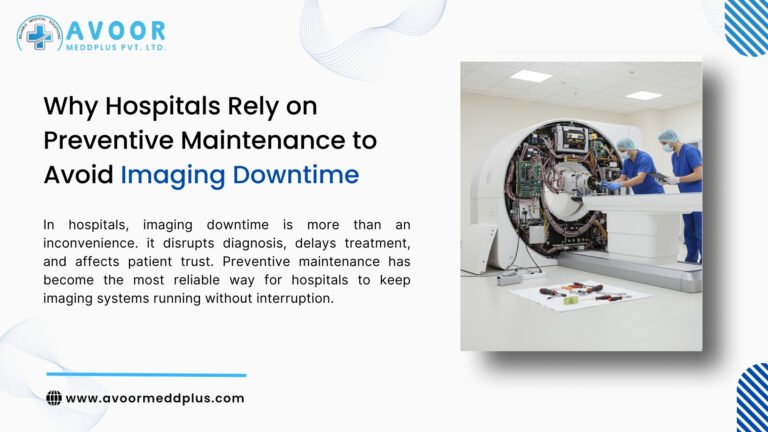

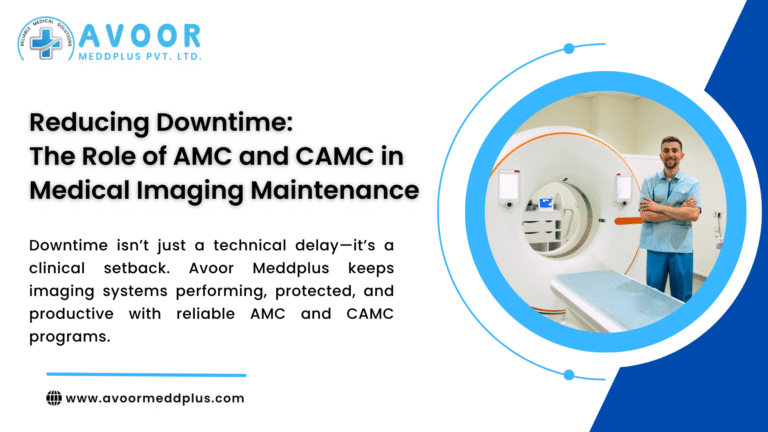

2. Role of Preventive Maintenance

Preventive maintenance goes beyond calibration—it involves routine inspection, testing, and component-level evaluation to keep imaging systems performing at their best. Avoor Meddplus provides structured maintenance programs to prevent breakdowns and extend system life while maintaining regulatory compliance.

3. Core Calibration Processes

Our engineers perform detailed SPECT/CT calibration that includes:

- Energy and uniformity calibration of gamma detectors

- Spatial resolution and linearity tests

- CT subsystem calibration for density and attenuation mapping

- Quality assurance using NEMA and AERB-standard phantoms

Each step ensures that imaging data remains consistent, reproducible, and diagnostically accurate.

4. Benefits of Regular SPECT/CT Calibration and Preventive Maintenance

- Enhanced image accuracy: Clear, uniform images support confident diagnoses.

- Improved uptime: Reduced technical downtime ensures operational efficiency.

- Longer equipment life: Regular care reduces wear and tear on key components.

- Regulatory compliance: Meets OEM and medical imaging quality standards.

- Reduced operating costs: Fewer breakdowns mean lower service expenses.

5. Impact on Diagnostic Accuracy

Calibration directly affects quantitative results such as Standard Uptake Value (SUV) and attenuation correction in hybrid imaging. A properly calibrated system guarantees that every scan reflects true patient physiology, ensuring precision in treatment planning and follow-up evaluations.

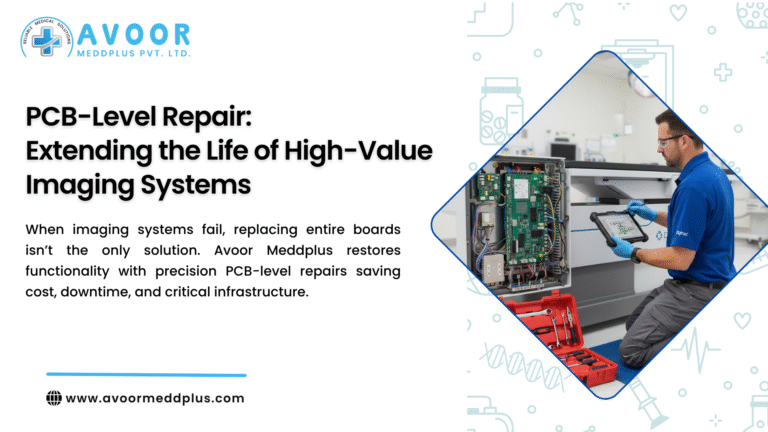

6. Key Components That Require Regular Calibration

- Gamma camera detectors and collimators

- X-ray tube and CT detectors

- Photomultiplier tubes (PMTs)

- Gantry and alignment sensors

- Image processing software and reconstruction algorithms

At Avoor Meddplus, we ensure every component functions in harmony, preventing data mismatch between the SPECT and CT systems.

7. Calibration Frequency & Maintenance Schedules

Based on system usage and workload, calibration is recommended:

- Daily: QC checks for uniformity and energy peak verification

- Monthly: Image quality and alignment validation

- Quarterly: Full system calibration and preventive maintenance

- Annually: OEM-level deep service and component replacement

Avoor Meddplus tailors maintenance schedules to your imaging workload for maximum efficiency.

8. Preventive Maintenance and Compliance Standards

Our preventive maintenance protocols follow AERB, NABH, and OEM requirements. Every service includes documentation, calibration certificates, and system performance reports to ensure compliance during audits and quality inspections.

9. Integration with Predictive Diagnostics

Avoor Meddplus integrates predictive maintenance technology that identifies early deviations in image quality and detector performance. This allows preemptive correction before any clinical impact occurs, keeping your system always ready for patient care.

10. Why Choose Avoor Meddplus for SPECT/CT Calibration

- OEM-certified engineers with nuclear imaging expertise

- Advanced testing and calibration instruments

- Comprehensive maintenance plans for all major brands

- Fast response and on-site support across India

- Proven record of increasing uptime and image precision

Conclusion

Regular SPECT/CT calibration and preventive maintenance are essential to sustain diagnostic accuracy, operational reliability, and patient safety. Avoor Meddplus ensures every calibration is executed to the highest OEM and clinical standards, empowering hospitals and diagnostic centers with dependable imaging systems that perform flawlessly, scan after scan.