Introduction

In healthcare, confidence in medical equipment maintenance is just as important as the technology itself. Hospitals and diagnostic centers depend on imaging and biomedical equipment to deliver accurate diagnoses, safe procedures, and uninterrupted patient care. However, confidence does not come only from fixing a problem—it comes from how the problem is handled.

This is where transparent service processes equipment maintenance becomes critical. Clear communication, documented workflows, and visible quality checks help hospitals trust that their equipment is being maintained safely, correctly, and in full compliance with standards. At Avoor Meddplus, transparency is embedded into every stage of equipment service, building long-term confidence with healthcare providers.

1. What Are Transparent Service Processes in Equipment Maintenance?

Transparent service processes refer to clearly defined, well-documented, and openly communicated maintenance activities. Instead of treating service as a “black box,” transparent providers ensure hospitals understand:

- What fault was identified

- Why the issue occurred

- What corrective action was taken

- Which parts were repaired or replaced

- What tests and validations were performed

- How compliance was ensured

This visibility transforms maintenance from a reactive task into a trusted partnership.

2. Why Confidence Matters in Equipment Maintenance

Medical equipment directly affects patient safety and clinical decision-making. When maintenance processes are unclear, hospitals may worry about:

- Hidden shortcuts in repairs

- Incomplete calibration

- Non-compliance with safety standards

- Risk of repeat failures

- Audit and regulatory exposure

Transparent service processes equipment maintenance eliminate these concerns by creating accountability and clarity at every step.

3. 5 Proven Ways Transparent Service Processes Build Confidence

1️⃣ Clear Fault Diagnosis and Root Cause Explanation

Confidence begins with understanding the problem. Transparent service providers clearly explain:

- The nature of the fault

- The root cause

- Whether it was mechanical, electronic, software-related, or environmental

When biomedical teams understand why a failure occurred, they trust that the solution is correct—not temporary.

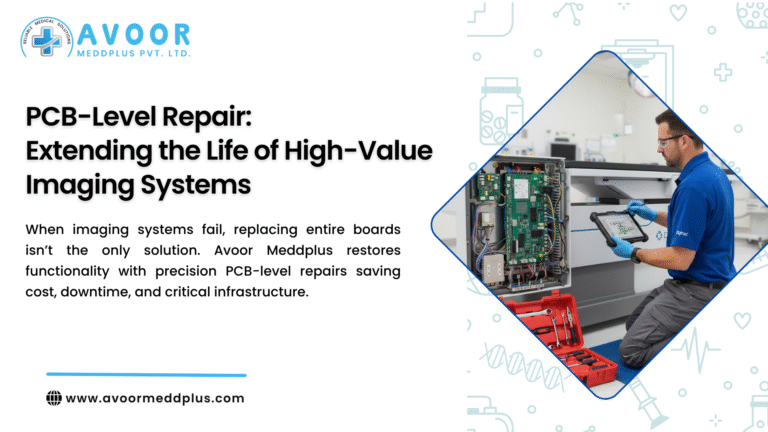

2️⃣ Step-by-Step Repair and Maintenance Documentation

Detailed service reports are a cornerstone of transparency. These reports include:

- Work performed

- Parts repaired or replaced

- Calibration actions taken

- Safety tests completed

Transparent documentation reassures hospitals that maintenance was performed methodically and professionally.

3️⃣ Visibility into Calibration and Quality Checks

Repair alone is not enough validation is critical. Transparent service processes equipment maintenance include visible proof of quality, such as:

- Calibration certificates

- Image quality test results

- Radiation output verification

- Electrical safety test records

These validations demonstrate that equipment is not only operational but clinically safe and accurate.

4️⃣ Compliance and Audit-Ready Reporting

Healthcare facilities must comply with strict regulatory requirements. Transparent service providers ensure that:

- Preventive maintenance logs are complete

- Calibration schedules are followed

- Safety checks are documented

- Service history is traceable

Audit-ready documentation builds confidence with hospital management, quality teams, and regulators.

5️⃣ Honest Communication and Predictive Guidance

Transparency also means honesty. Trusted service partners communicate:

- Equipment health status

- Potential future risks

- Recommended preventive actions

- Remaining life of critical components

Instead of surprises, hospitals receive foresight—strengthening confidence in maintenance decisions.

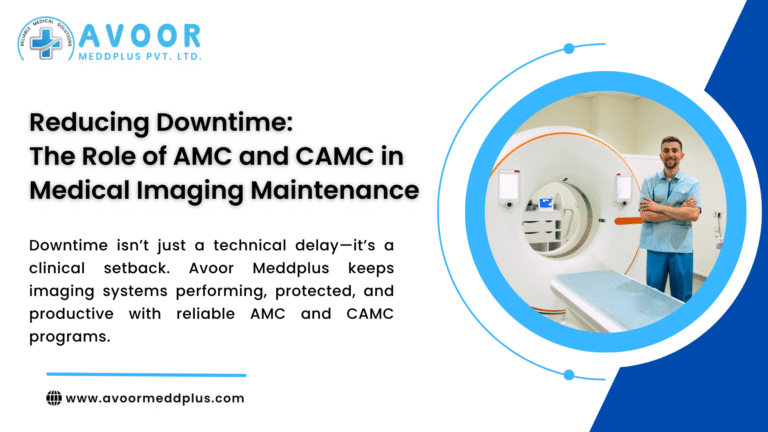

4. How Transparent Processes Reduce Downtime and Risk

Unclear service practices often lead to repeat failures and extended downtime. Transparent service processes equipment maintenance reduce these risks by:

- Addressing root causes, not symptoms

- Ensuring proper calibration after repair

- Preventing missed safety steps

- Supporting proactive maintenance planning

Hospitals gain confidence knowing downtime is minimized through disciplined, visible workflows.

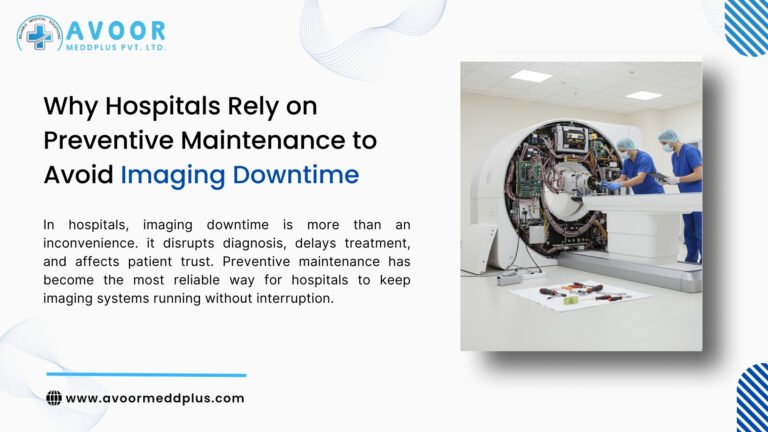

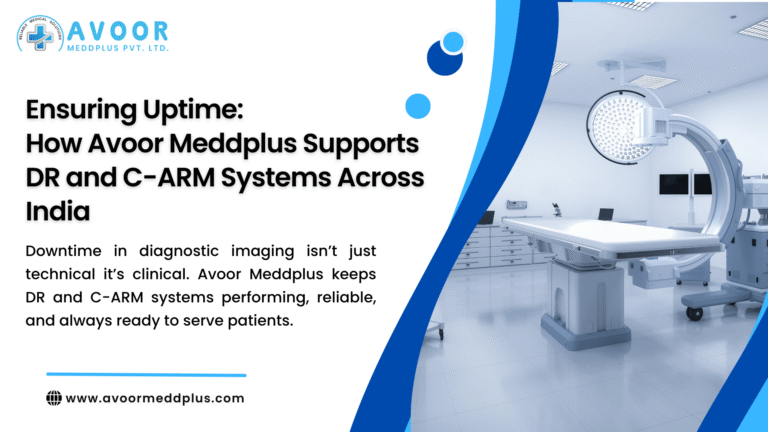

5. Transparency Across Imaging Modalities

Transparent service processes apply consistently across all equipment types:

CT & PET/CT Systems

- Gantry and detector calibration records

- Tube and cooling system test reports

- Dose accuracy documentation

DR & CR Systems

- Flat-panel detector calibration logs

- Exposure linearity test results

- Image uniformity reports

C-ARM Systems

- Fluoroscopy output verification

- Radiation safety checks

- Mechanical stability inspection records

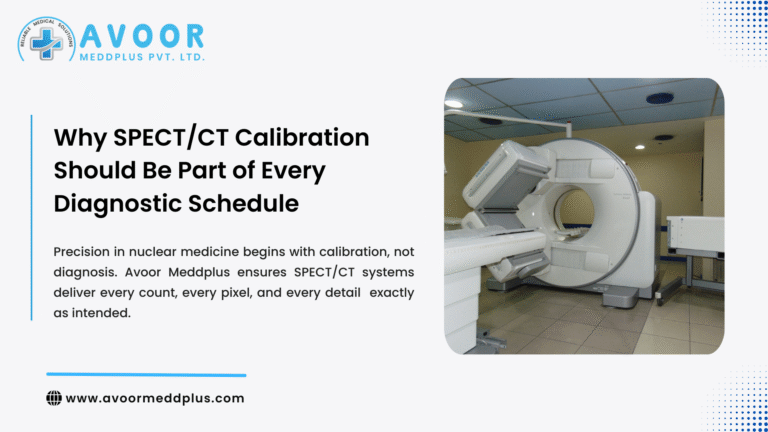

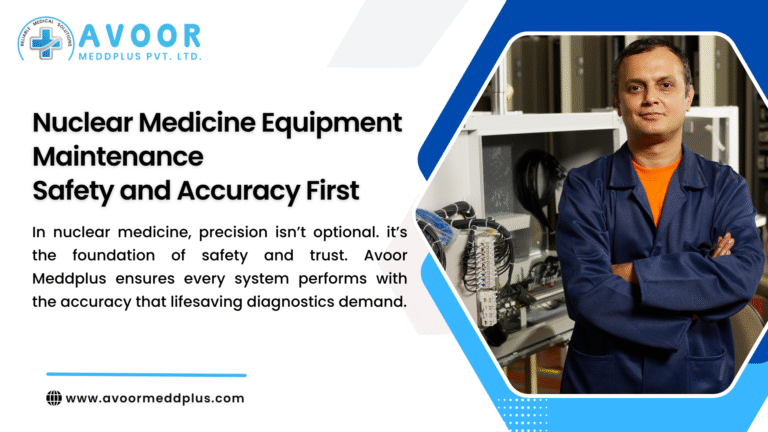

SPECT/CT & Nuclear Medicine

- Energy peaking documentation

- Uniformity and COR calibration reports

- Fusion alignment validation

This consistency reinforces trust across all departments.

6. Role of Biomedical Engineers in Transparent Maintenance

Certified biomedical engineers are key to transparency. Their expertise ensures that:

- Maintenance follows standardized procedures

- Technical explanations are accurate and clear

- Safety checks are never skipped

- Documentation is precise and complete

Transparent service is not just a system—it is driven by disciplined engineering practices.

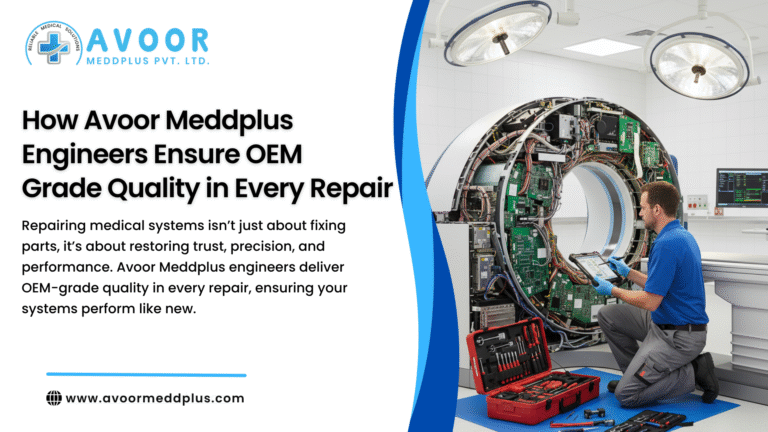

7. How Avoor Meddplus Delivers Transparent Service Processes

Avoor Meddplus builds confidence through transparency by providing:

- Clear fault diagnosis and root-cause analysis

- OEM-grade repair and calibration

- Detailed service and compliance reports

- Preventive maintenance schedules

- Safety and performance validation records

- Open communication with hospital teams

- Nationwide service consistency

Every service activity is designed to be understandable, verifiable, and accountable.

8. Long-Term Benefits of Transparent Maintenance

Hospitals that work with transparent service partners experience:

- Higher trust in equipment performance

- Fewer repeat breakdowns

- Improved audit outcomes

- Better planning for upgrades and replacements

- Stronger collaboration between clinical and engineering teams

Transparency turns maintenance into a confidence-building process rather than a risk factor.

Conclusion

In modern healthcare, confidence is built through clarity, accountability, and consistency. Transparent service processes equipment maintenance improve trust by making every action visible, every decision explainable, and every outcome verifiable.

When hospitals can clearly see how equipment is maintained, tested, and validated, confidence naturally follows. Through disciplined workflows, compliance-focused documentation, and honest communication, Avoor Meddplus helps healthcare providers trust not only the repair—but the process behind it.